Amidst the rapid advancements in medical technology, precision medical injection molded parts have emerged as an indispensable component in numerous medical devices and instruments. Today, Yize's editor will delve deep into why these high-tech medical components are increasingly favoring custom-made precision medical injection molded parts. This preference is closely tied to their distinct characteristics, which we will now uncover together.

1. The Artistic Presentation of Complex Surfaces

Precision medical injection molded parts, such as laryngoscopes, surgical instruments, various medical consumables, and high-end medical equipment, often feature designs that integrate multiple complex surfaces. The construction of these surfaces is so intricate that it sometimes requires advanced mathematical calculations for perfect rendering. They are not only the crystallization of technology but also a harmonious blend of art and science.

2. Pursuit of Extreme Precision at the Micrometer Level

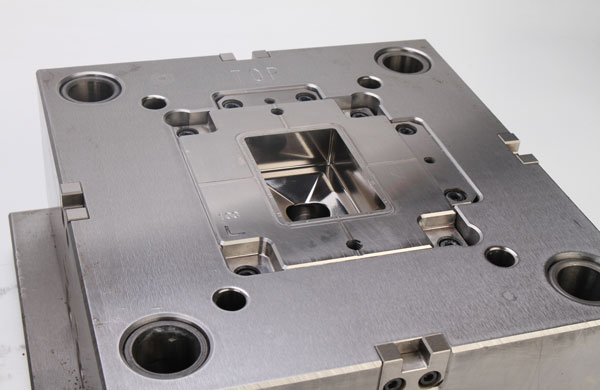

In the realm of precision medical injection molding, processing accuracy is a crucial benchmark for measuring quality. A complete mould is precisely constructed from components such as the female mold, male mold, mold base, and even multiple assembled modules. Each part's combination, whether it's the tight fit between the upper and lower molds, the seamless integration of inserts and cavities, or the precise alignment of modules, must achieve micrometer-level accuracy to ensure the perfection of every injection molded part.

3. Exquisite Craftsmanship, Meticulous Carving through Multiple Processes

From milling to boring, from drilling to reaming, and then to the fine tapping of threads, the processing of precision moulds is akin to a meticulous craftsmanship feast. Each process is a testament to skill and a commitment to detail, collectively contributing to the exceptional quality of precision medical injection molded parts.

4. Smart Management of Repeated Production and Lifecycle

Moulds, as the cornerstone of precision medical injection molding, have a limited lifespan. However, each repeated production cycle is a precise balance of efficiency and cost. When a mould completes its mission, a new one immediately takes over, ensuring continuity and stability in the production line. This is an indispensable aspect of smart management in the production of precision medical injection molded parts.

About Yize Mould

Since its establishment in 2007, Dongguan Yize Mould Co., Ltd. has been rooted in Dongguan, a manufacturing hub, leveraging its convenient transportation and logistics network to specialize in the design and manufacture of precision moulds as well as the production of precision injection molded products. The company's business covers various fields such as automotive connectors, medical product injection molding, clean injection molding, custom PFA injection molding, and more. It provides a comprehensive range of solutions from product design, mould manufacturing, injection molding, assembly, to after-sales service, making it a trusted partner in the medical and numerous other industries.

Let us witness the extraordinary appeal of precision medical injection molded parts together and explore the infinite possibilities of medical technology!