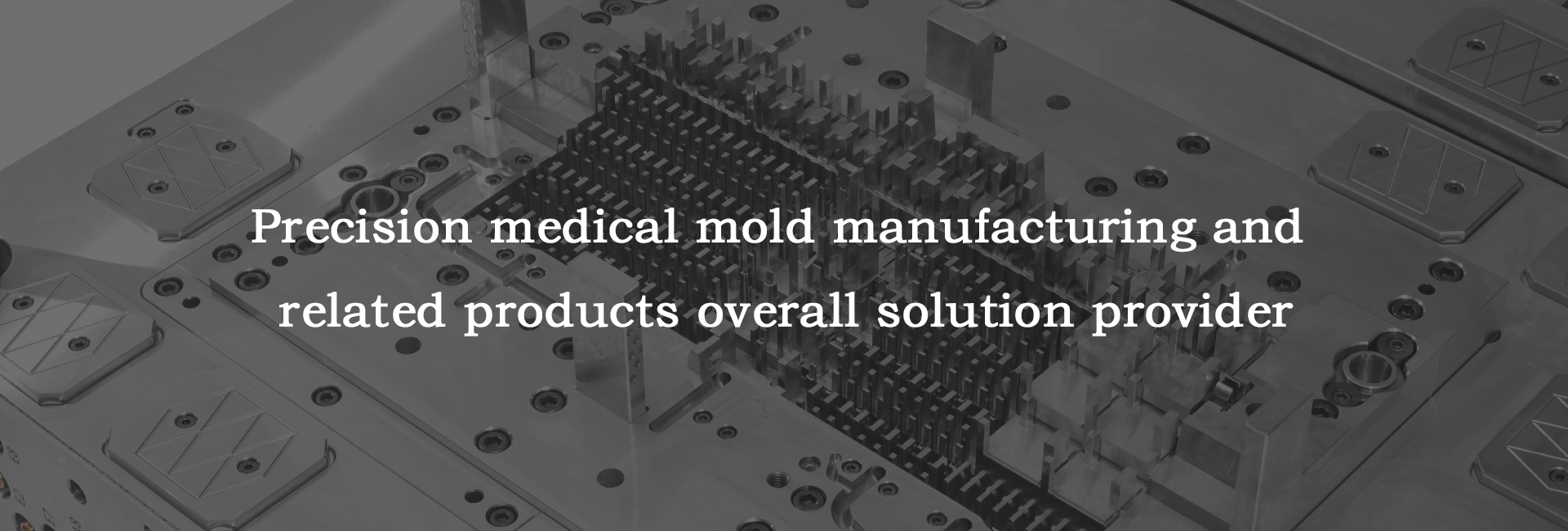

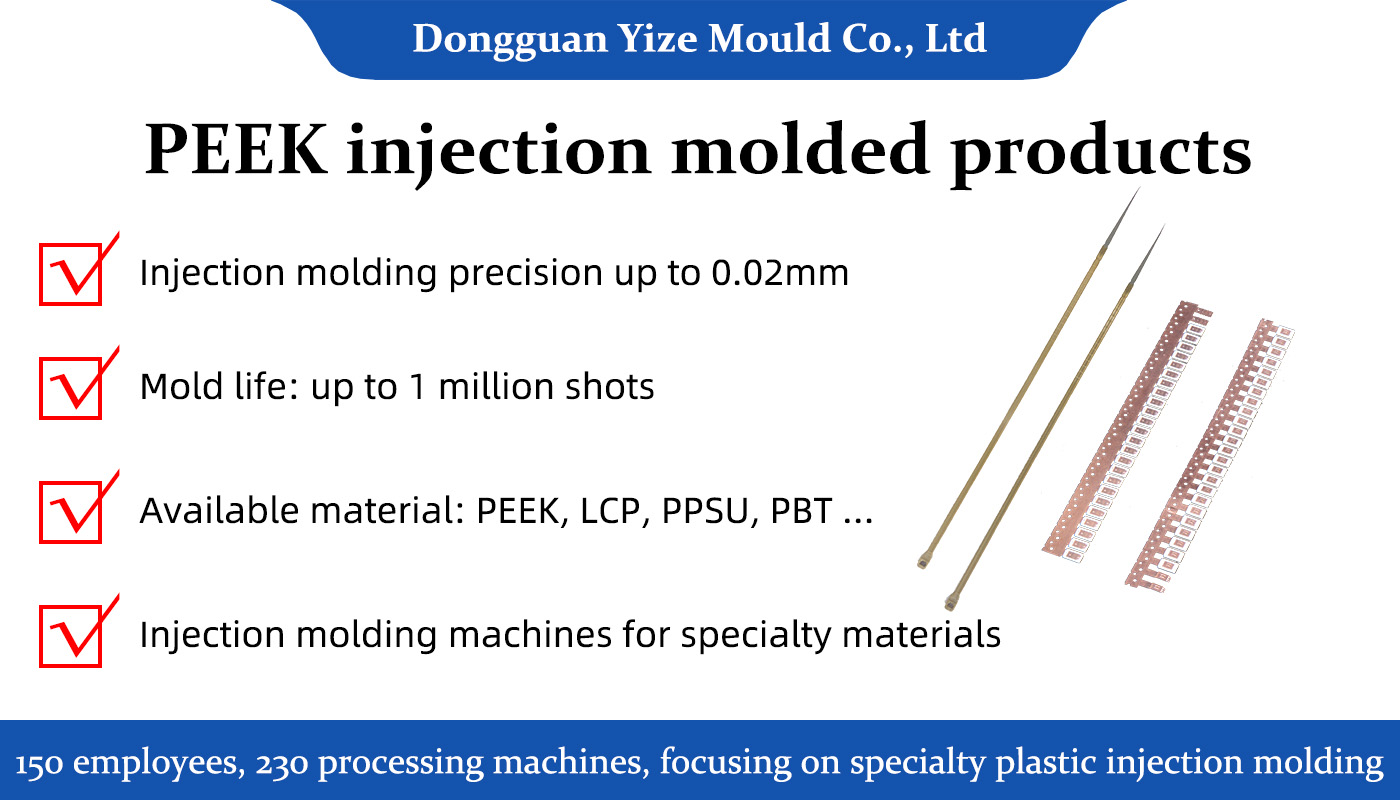

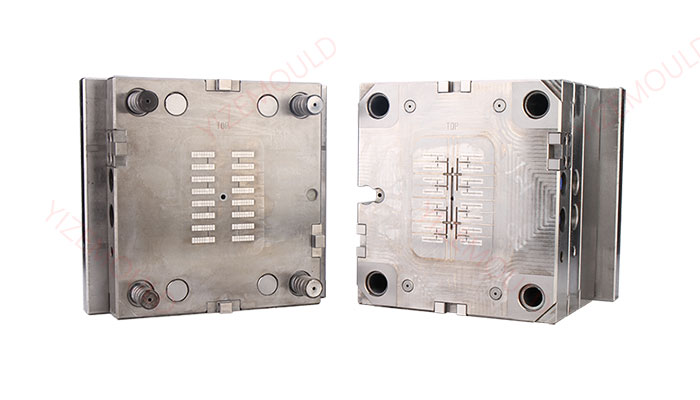

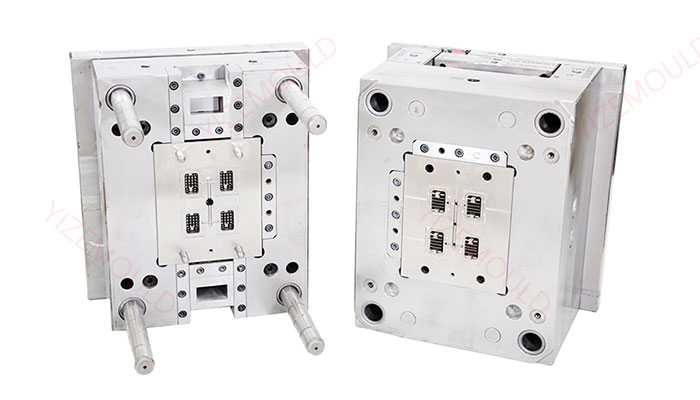

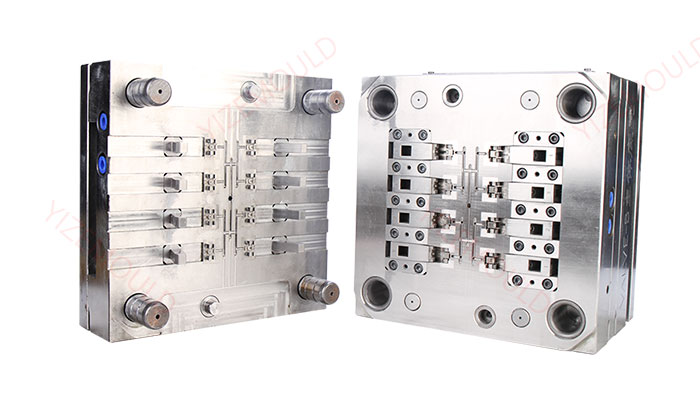

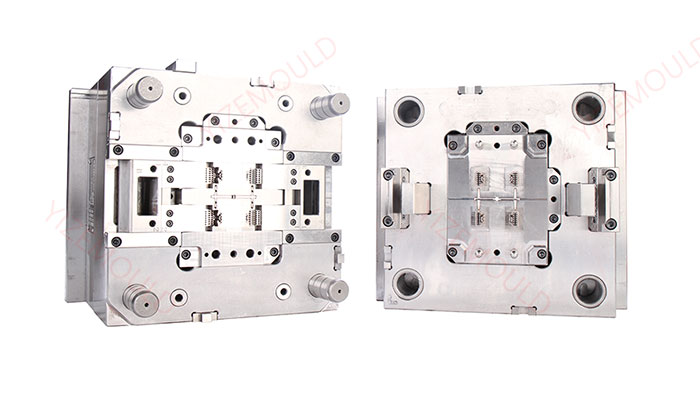

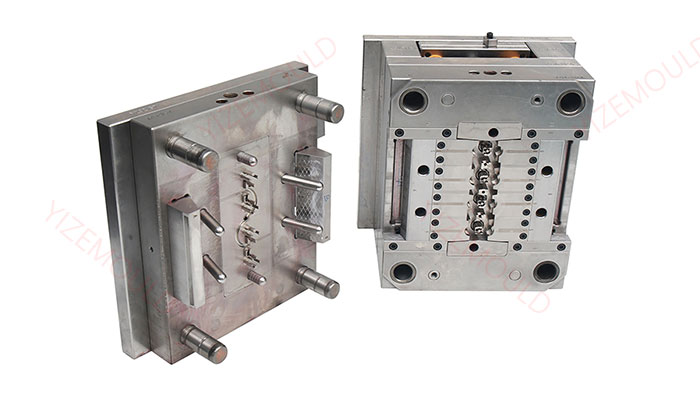

Analysis of Design Key Points for Precision Injection Molds

2025-11-17

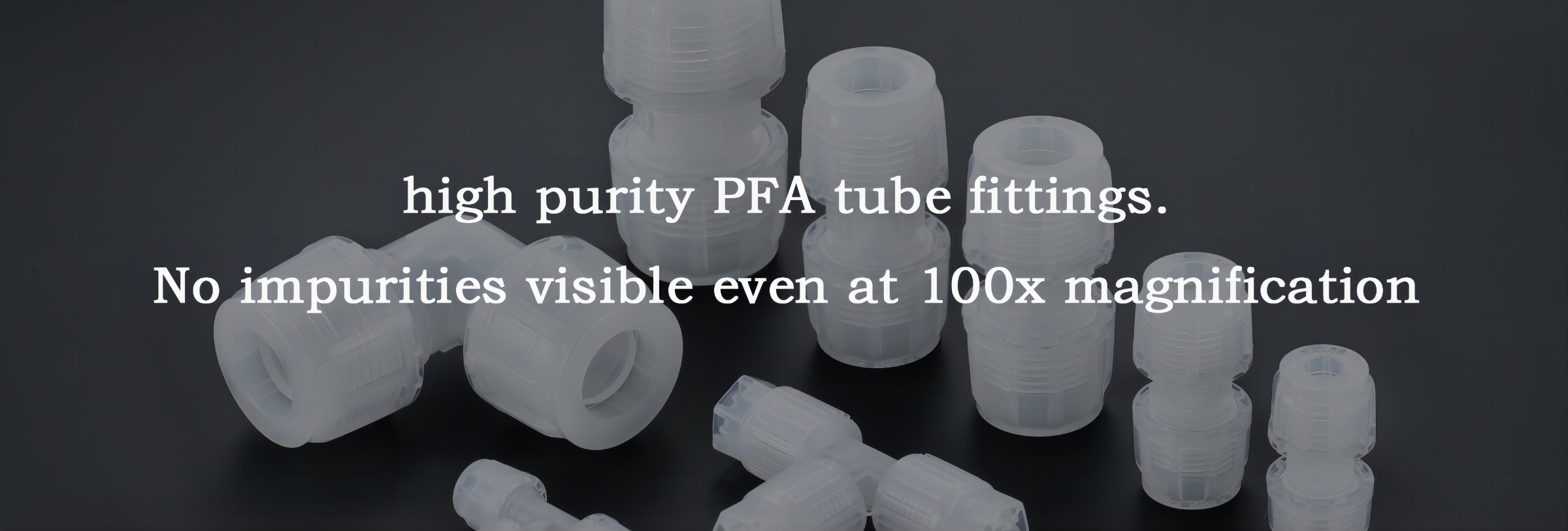

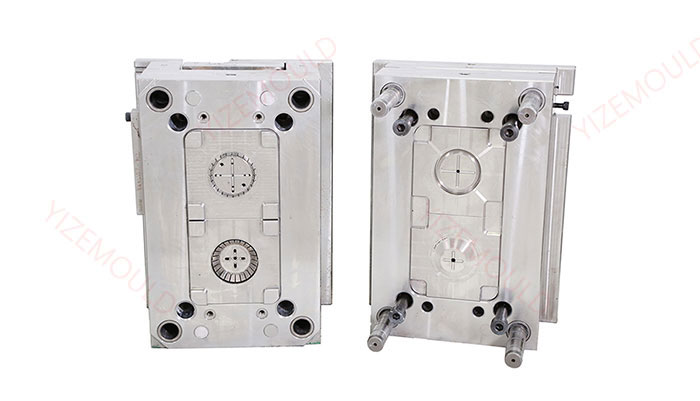

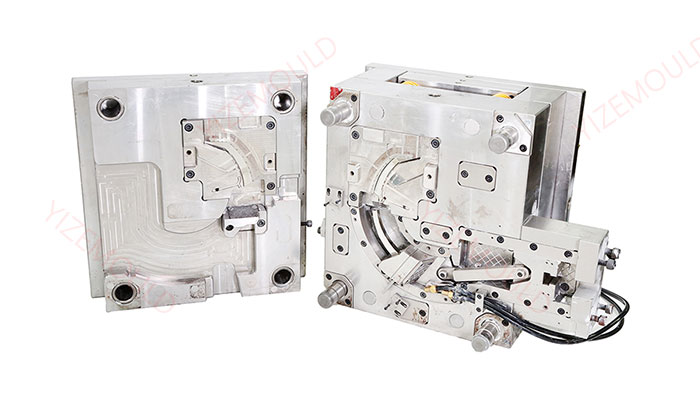

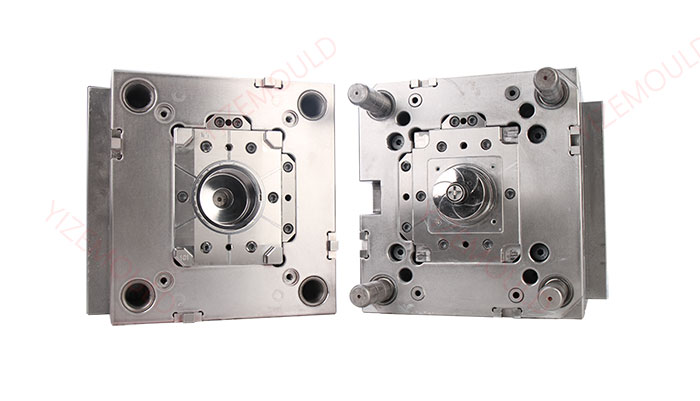

The design of precision injection molds is a complex and crucial process, and its design quality directly affects the precision, quality, and production efficiency of injection-molded products