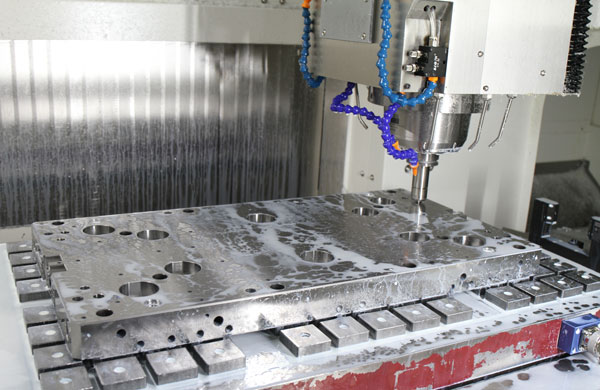

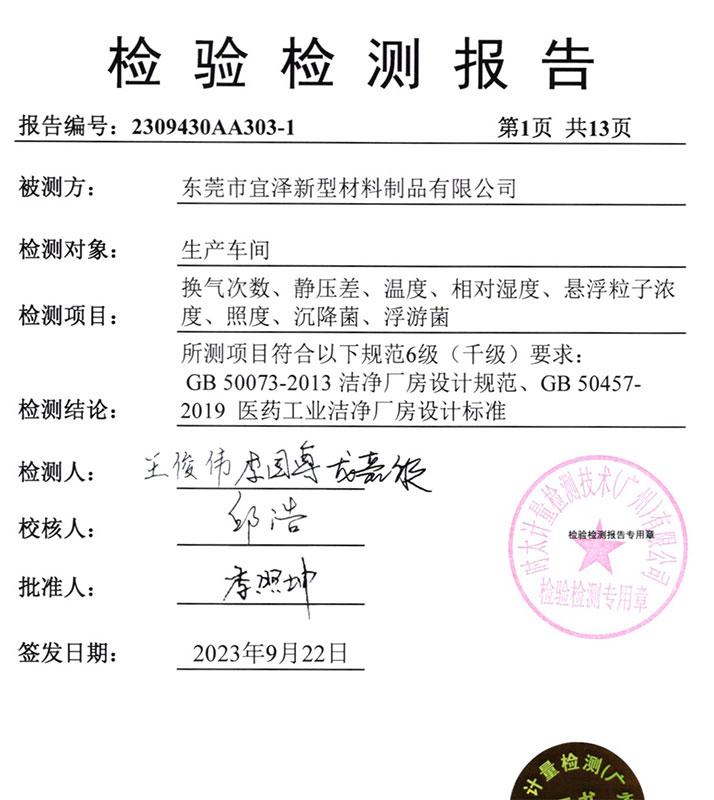

Class 10,000 dust-free injection molding workshop, to create a new benchmark for high-quality produc

Dust-free workshop, also known as clean-room, is a specially designed room according to the production requirements. In this room, we need to temperature, humidity, air pressure, airflow speed and distribution, noise, vibration, lighting and static electricity and other environmental factors are strictly regulated to ensure that they are in a specific standard range. The clean room is unaffected by changes in outside air conditions and maintains the key performance indicators originally set wi…

2024-04-24