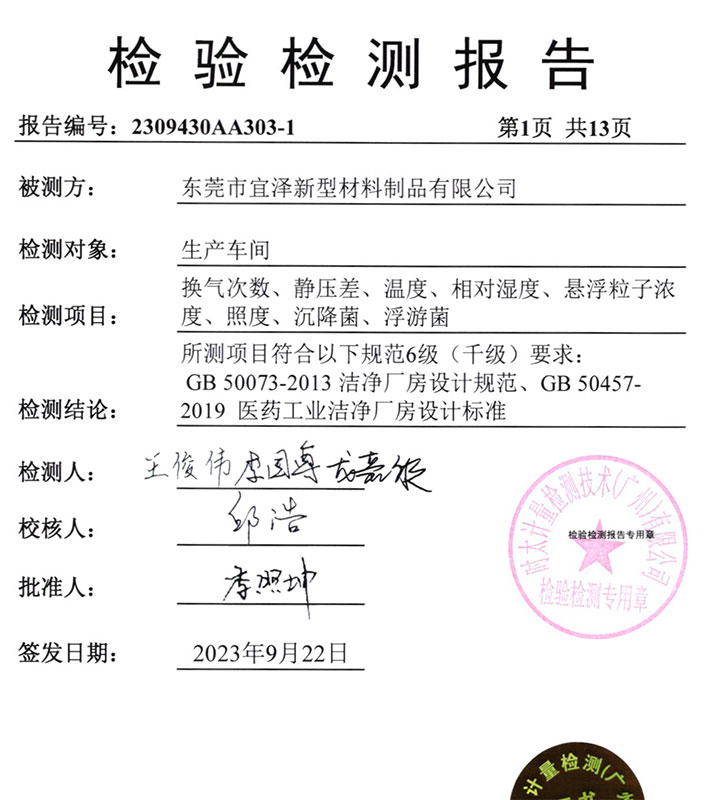

In the injection molding industry, the quality and cleanliness of products have a crucial impact on their value. Recently, Yize Mould successfully passed the inspection of class 1000 cleanroom, indicating that our production environment and technical strength have reached a new height.

"class 1000 cleanroom" refers to a standard for cleanliness of a cleanroom, where the number of particles larger than 0.5 microns per cubic foot of air does not exceed 1000. This high-cleanliness production environment has extremely high requirements for product quality and precision, and is widely used in precision machinery, medical equipment, aviation and other fields.

Yize Mould has already passed the ISO13485 medical certification before, and now it has also passed the inspection of class 1000 cleanroom. It means that we have a greater development space in the medical injection industry. With these two certifications, we will be able to play a greater role in the medical injection molding industry, and provide higher quality and more exquisite injection-molded products to customers worldwide.

Currently, our main products include medical injection mold, plastic medical device consumables, pipette tips or centrifuge tubes, deep well plates, PS culture dishes, etc. These products not only have a high degree of technical content but also have a wide range of applications in the medical industry.

By continuously improving our technical strength and production level, we will provide higher quality and more exquisite injection-molded products to medical industry clients. We believe that through our unremitting efforts, we will achieve greater success in the medical industry and make greater contributions to the development of human health.

Finally, if you are interested in our company, you can also learn about our production process or contact us by clicking here.