In the design of injection molds, the selection of the parting surface is undoubtedly a crucial aspect. Parting surfaces come in various forms, commonly including horizontal, stepped, angled, and irregular parting surfaces. The design of the parting surface directly impacts the quality of the molded parts and the smoothness of the processing, therefore, we must carefully consider and prudently choose the parting surface. Designers at Yize Mold base their selections on the following key dimensions.

Firstly, they consider whether the molded parts can be easily and smoothly ejected from the injection mold. An ideal parting surface location should ensure that the molded parts do not get stuck in the mold cavity during ejection, and that the plastic parts remain on the moving mold plate side during mold separation, facilitating the design and implementation of the ejection mechanism.

Secondly, the selection of the parting surface should strive to simplify the structure of the injection mold as much as possible. During the design process, we should comprehensively consider and choose parting surfaces that can make the mold structure simpler and easier to manufacture, thereby reducing production costs and improving production efficiency.

Furthermore, the venting of gases within the injection mold cavity is also an aspect that cannot be ignored when selecting the parting surface. Gas venting mainly relies on the design of venting grooves on the parting surface, therefore, the parting surface should be strategically placed at the end of the flowing melt to ensure smooth gas venting and avoid adverse effects on the quality of the molded parts.

In addition, ensuring the quality of the molded parts is the primary premise of injection mold design. Regardless of how the parting surface is selected, it must be ensured that the quality of the mold itself and the molded parts meets the established standards, which is an unshakable principle in any injection mold design.

Lastly, the selection of the parting surface should also fully and reasonably utilize existing equipment. During the design process, we should fully consider the compatibility between the injection mold and the equipment, and choose parting surfaces that can perfectly match the equipment to fully leverage the equipment's performance and improve production efficiency.

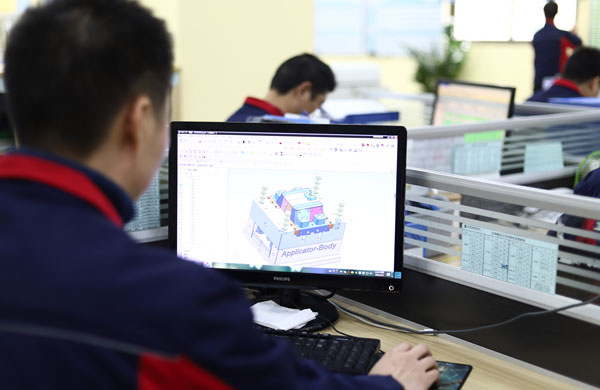

Dongguan Yize Mold Co., Ltd., established in 2007, is located in Dongguan, the manufacturing capital, with convenient transportation and logistics. As a company engaged in precision mold design and manufacturing, as well as precision injection molding products production for many years, we specialize in providing a complete set of solutions for the design, precision mold manufacturing, injection molding and assembly, and after-sales service of automotive connectors, medical product injection molding, cleanroom injection molding, PFA custom injection molding, and other products. If you have any needs or questions, please feel free to contact us at any time (Phone/WeChat/WhatsApp: 13302615729), and we will sincerely serve you!