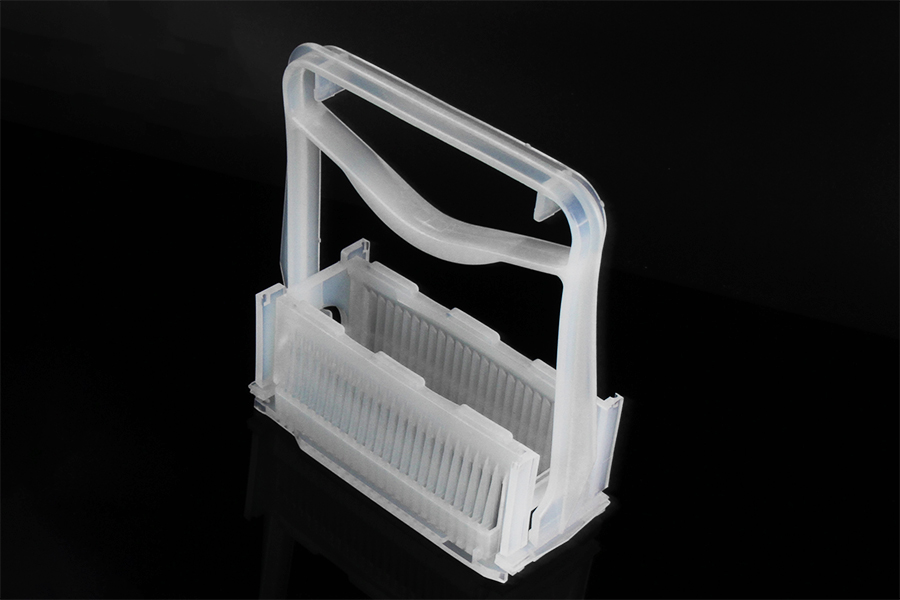

PFA Wafer Cassette plays an important role in the semiconductor industry. PFA is a material with excellent chemical resistance and high temperature stability, which is very suitable for Wafer Cassette in semiconductor manufacturing process.

PFA Wafer Cassette is used to protect and transport silicon wafers in the semiconductor manufacturing process. Silicon wafers are one of the key components in semiconductor manufacturing, and the role of Wafer Cassette is to ensure that the wafers are not damaged or contaminated during the manufacturing process.

Protecting the wafer surface: PFA material has very low adhesion, which can effectively prevent the wafer from adhering to the surface of the carrier and prevent scratches and contamination.

Provide a stable environment: PFA Wafer Cassette can provide a stable temperature and humidity environment to ensure that wafers are not disturbed by temperature changes, humidity changes and other environmental factors during the manufacturing process.

Convenient Handling and Operation: PFA Wafer Cassette has low surface energy and smooth surface, which is easy to clean and handle, facilitating operators to load and unload wafers during the manufacturing process.

High purity material: PFA material has excellent chemical stability, whether it is chemicals or gases used in the manufacturing process, PFA material can provide good chemical resistance, which helps to maintain the purity of silicon wafers.

Used for semiconductor wafers, wafers, glass, LCD screen cleaning, corrosion bearing; used in solar cell wafer cleaning equipment, used to carry square solar cell wafers. This product can be in 100 ℃ below the NaOH solution, HCl solution, HF and other solutions for silicon wafer cleaning, conversion, and long-term use of non-deformation, no pollution of silicon.

Q: What needs to be provided for a precision mold quote?

A: Usually you need to provide 2D drawings and 3D drawings to us for faster mold quotation and manufacturing. Supported 2D drawing formats are: AI, PDF, DWG, CAD, DXF, DLG, etc. Supported formats for 3D drawings are: STP, IGS, etc.

Q: We don't have product drawings, only samples, can you process them?

A: We offer sample processing, but providing 2D or 3D drawings will allow us to understand your needs more accurately and quote faster.

Q: How about your mold making capability?

A: We have professional mold designers, and experienced technicians. There are more than 140 personnel and more than 180 sets of imported advanced mold manufacturing equipment. Learn more about us.

Q: What plastics can you process for injection molding?

A: The injection molding materials we can process are: PFA, PTFE (Teflon), PA66, PEI, PVDF, PBT, POM, PPS, PEEK, LCP, PPSU, and so on. Our company can not only customize PFA Wafer Cassette with different shapes and sizes according to customer's drawings, but also can customize injection molding PFA products.

Q: What if the processed mold does not meet the requirements?

A: Our factory strictly installs the accuracy of the drawings provided by the customer for manufacturing, but also with the customer to communicate the use of molds and precision requirements, if there is a mold does not meet the customer's requirements, if it is a problem with our manufacturing, we are responsible for arranging to redo. But if it is due to the buyer's drawings are incorrect leading to the scrapping of the product will be negotiated separately.