In today's increasingly competitive market, plastic mold manufacturers are facing unprecedented challenges. How to stand out among numerous peers and produce cost-effective plastic molds with market competitiveness has become a question that every plastic mold manufacturer must ponder. Below, I will elaborate on four key strategies for enhancing the advantages of plastic mold manufacturing from four aspects.

I. Pursuit of Excellence: Improving Design and Manufacturing Precision

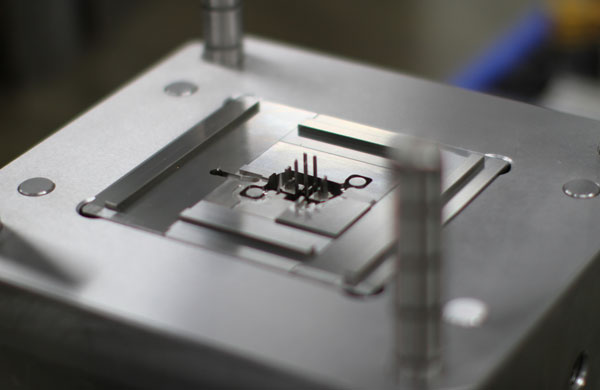

The precision of plastic molds is a crucial indicator of their quality, directly determining the precision and quality of plastic parts. To ensure that plastic parts can meet high precision requirements, the precision of the molding components must exceed the precision standards of the plastic parts themselves. At the same time, the overall structural design of the plastic mold must also ensure high precision. Only in this way can plastic products that meet or even exceed customer expectations be produced. Therefore, improving design and manufacturing precision is an indispensable aspect for plastic mold manufacturers.

II. Extending Lifespan: Prolonging the Service Life of Plastic Molds

Plastic molds, as high-cost production equipment, have a service life that directly correlates with production costs. In conventional production scenarios and mass production, the service life of molds becomes a key factor in measuring their competitiveness. Except for special cases such as small-batch production or new product trials, plastic molds should pursue a longer service life to reduce the production cost per unit product, thereby occupying a more favorable position in the market.

III. Racing Against Time: Shortening the Manufacturing Cycle of Molds

The length of the mold manufacturing cycle directly reflects the technical strength and production management level of the manufacturer. To meet the rapidly changing market demand and improve product competitiveness, plastic mold manufacturers must strive to shorten the manufacturing cycle of molds while ensuring quality. This not only allows for quick response to customer needs but also wins more market opportunities for the manufacturer.

IV. Quality at a Reasonable Price: Balancing Cost Control and Quality Assurance

The cost of plastic molds is influenced by various factors, including the complexity of the mold structure, the selected materials, manufacturing precision, and processing methods. While meeting the requirements of plastic parts, manufacturers should reasonably design the mold structure and formulate efficient processing processes, striving to minimize the manufacturing cost of plastic molds while ensuring quality. Only in this way can they maintain a price advantage in the fierce market competition and win the favor of more customers.

In summary, enhancing the advantages of plastic mold manufacturing is not achieved overnight. It requires manufacturers to make joint efforts in improving design and manufacturing precision, prolonging mold service life, shortening manufacturing cycles, and controlling costs, constantly pursuing excellence to remain invincible in the fierce market competition.