For vacuum bubbles caused by differential cooling rates between the outer surface and the core of thick-walled products, solutions include:

Designing reasonable gate and runner sizes based on wall thickness, with gate height typically at 50%-60% of product wall thickness.

Leaving some supplementary injection material until the gate seals.

Extending the injection time slightly beyond gate sealing.

Reducing injection speed while increasing injection pressure.

Using materials with higher melt viscosity.

Bubbles due to volatile gases can be resolved by:

Adequately pre-drying the resin.

Lowering the resin temperature to prevent gas formation from decomposition.

Bubbles caused by poor flow can be addressed by:

Increasing the temperature of the resin and mold.

Enhancing the injection speed.

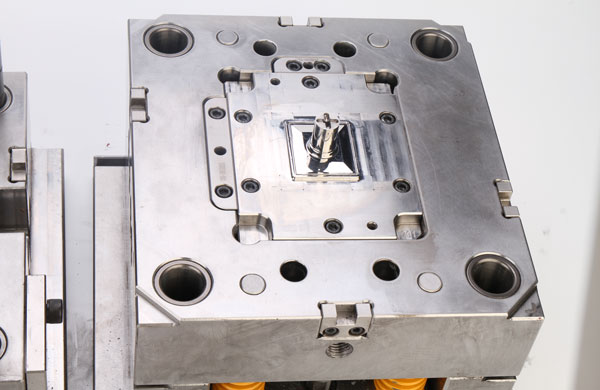

Dongguan Yize Mould Co., Ltd. was founded in 2007, is headquartered in the manufacturing capital of Dongguan, convenient transportation and logistics, is engaged in many years in the design and manufacture of precision molds and precision injection molding products manufacturer, the company focuses on the automotive connectors, medical products injection molding, dust-free plastic injection molding, custom injection molding of PFA products such as design, precision mold manufacturing, injection molding and assembly, after-sales service as a whole set of solutions. The company specializes in product design, precision mold manufacturing, injection molding and assembly, and after-sales service.