The design of plastic product shapes not only needs to facilitate easy molding but also simplify the structure of plastic molds. So, what factors should be considered in the shape design of plastic products?

Design of draft angles.

The shape design of plastic products should also contribute to enhancing product strength and stiffness.

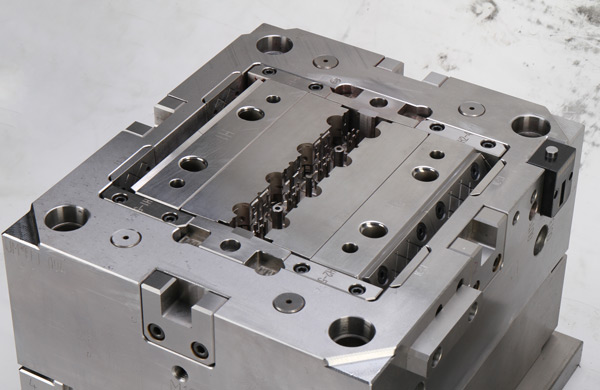

Geometric shape of plastic parts: The internal and external shapes of plastic products need to be easily molded. During design, side holes, undercuts, or holes perpendicular to the demolding direction of plastic parts should be avoided to prevent the adoption of complex plastic mold structures.

Wall thickness of plastic products: Whether the wall thickness of plastic products is reasonable directly affects the product's usage and molding quality. The wall thickness should not only meet the requirements for sufficient strength and stiffness during product use but also withstand the impact and vibration of the demolding mechanism during demolding. However, it should be noted that the wall thickness should not be too large. Excessive wall thickness can easily lead to injection molding defects such as bubbles, shrinkage, and warpage.

To summarize, the design of plastic product shapes is a comprehensive consideration that integrates technology, aesthetics and cost-effectiveness. Only a deep understanding and accurate grasp of the above key elements, can stand out in the fierce market competition, to create both beautiful and practical quality products.