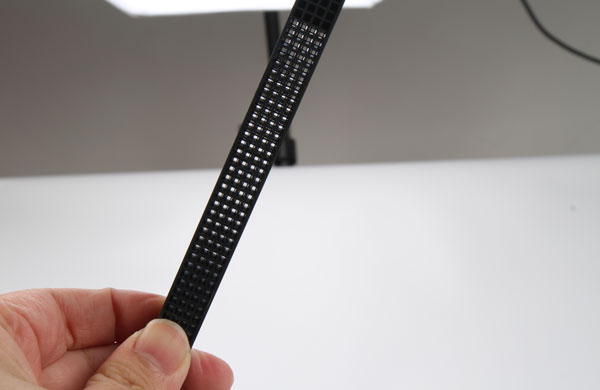

Fracture, or brittleness, refers to the phenomenon where plastic parts are prone to cracking or breaking in certain areas during injection molding. The presence of this phenomenon not only affects the appearance quality of the product but also poses a serious threat to its performance.

The possible causes of fracture mainly include the following:

Inappropriate drying conditions, leading to degraded material properties;

Improper setting of injection molding temperatures, failing to achieve optimal plasticization of the material;

Defects in the design of gates and gate systems, affecting the flow and filling of molten material;

Insufficient melt strength of the material itself, failing to meet the molding requirements.

To address these issues, we can proceed from the following aspects:

In terms of material selection:

Appropriate drying conditions should be set for the material before injection molding to ensure stable performance;

The proportion of recycled material should be appropriately reduced, and the amount of raw material should be increased to improve the overall quality of the product;

High-strength plastics should be used to fundamentally enhance the product's resistance to fracture.

In terms of mold design:

The sizes of the main runner, branch runner, and gate should be reasonably increased to optimize the flow path of molten material and reduce the risk of fracture.

In terms of machine selection:

A well-designed screw should be selected to ensure a more uniform temperature distribution during the plasticization process, thereby reducing the likelihood of fracture.

In terms of injection molding process:

The temperatures of the material cylinder and nozzle should be appropriately lowered to avoid damage to the material caused by excessively high temperatures;

Back pressure, screw speed, and injection speed should be reduced to minimize stress concentration during the molding process;

At the same time, material temperature and injection pressure should be increased to enhance melt strength and improve the product's resistance to fracture.

Address fracture in injection molding by optimizing material, mold design, machine selection, and process parameters.