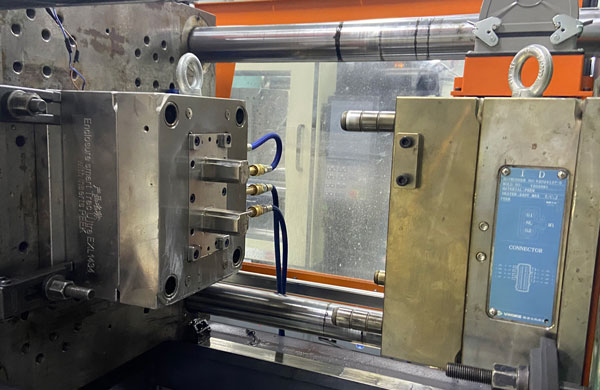

In the precise process of plastic injection molding, we often encounter a tricky problem – the gate becoming tightly adhered to the gate insert. Today, we will delve deeply into the causes of this phenomenon and explore effective solutions.

Calibration Deviation: Improper calibration between the gate insert of the plastic mold and the nozzle is often a major culprit in causing adhesion.

Overfilling: Excessive filling of plastic within the gate insert increases the risk of adhesion.

Inappropriate Temperature: A low nozzle temperature affects the fluidity and demolding properties of the plastic.

Incomplete Solidification: Especially in larger-diameter gates, if the plastic does not fully solidify within the gate, it can also lead to adhesion.

Poor Fit: If the arcuate surfaces of the gate insert and the nozzle do not fit well, it may form a flow channel resembling a "mushroom" shape, increasing the likelihood of adhesion.

Insufficient Draft Angle: An inadequately designed draft angle for the flow channel can also exacerbate the adhesion issue.

Precise Calibration: Realign the nozzle and gate insert to ensure precise alignment.

Reduce Pressure: Lower the injection pressure to reduce overfilling in the gate insert.

Optimize Screw Control: Decrease the time for the screw to advance, controlling the amount of plastic injected.

Increase Temperature: Raise the temperature of the nozzle or use an independent temperature controller to heat the nozzle, enhancing the fluidity of the plastic.

Extend Cooling Time: Increase the cooling time for the plastic mold, but a more recommended approach is to replace it with a gate insert that has a smaller gate.

Correct Fit: Precisely adjust the mating surfaces of the gate insert and the nozzle to ensure perfect alignment.

Adjust Draft Angle: Appropriately increase the draft angle of the flow channel to reduce resistance during demolding.

Through these detailed analyses and precise solutions, we can effectively address the issue of adhesion between the gate and the gate insert in plastic injection molding, thereby enhancing production efficiency and product quality.