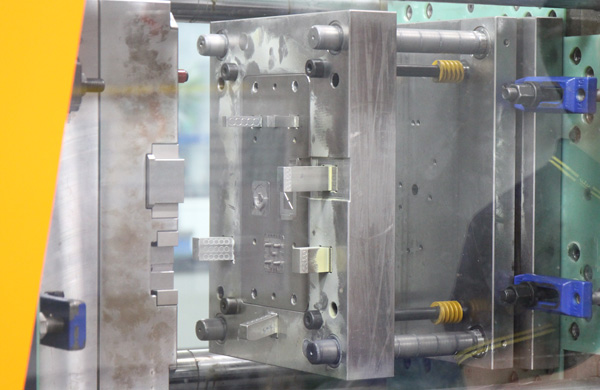

In the field of plastic injection molding, air traps, as a common defect, essentially refer to the phenomenon where air or gas is not promptly expelled from the mold during the injection process and is instead encapsulated within the mold cavity by molten plastic, thereby affecting the product's quality and appearance. Delving into the causes of air traps, we can analyze them from the following dimensions:

Excessive Injection Pressure: When the injection pressure of the injection molding machine is improperly set, excessive pressure can lead to rapid mold filling by molten plastic, leaving air or gas within the mold trapped and encapsulated by the plastic, forming air traps.

Uneven Wall Thickness: Significant differences in wall thickness in plastic part design can result in slower plastic flow in thinner areas while faster flow in thicker areas. This difference in flow rates may cause the plastic to surround and trap air or gas during flow, inducing air traps.

Gate Location Design: The position of the gate, where plastic enters the mold, is crucial. An improperly positioned gate can lead to molten plastic directly enveloping air or gas as it is injected, creating air pockets. Optimizing gate position to adjust the mold's filling path can effectively prevent air traps.

Matching of Runner and Gate Sizes: In multi-gate injection mold designs, precise calculation of runner and gate sizes is necessary to ensure balanced plastic flow. Improper sizes not only affect filling efficiency but may also cause plastic to encapsulate gas during flow, leading to air traps. Therefore, rational design of runner and gate sizes is key to avoiding air traps.

Mold Venting System: Effective mold venting is a crucial factor in ensuring injection molding quality. Poor mold venting design can result in air or residual gas within the mold being drawn in at the mold's closure, subsequently forming air traps during the injection process. Optimizing the venting system to ensure smooth gas expulsion is an effective means of addressing air trap issues.

In summary, while air traps in plastic injection molding may not be entirely avoidable, fine-tuning injection machine parameters, optimizing plastic product design, and improving mold structure and venting systems can significantly reduce the occurrence of air traps, thereby enhancing the overall quality of injection molded products. As plastic mold manufacturers, continuous attention to and improvement of these details are essential for enhancing competitiveness.