Today, We talk about the case study high precision plastic injection mold project of Our Company: the process from an idea to a reality.

A Polish plastic injection manufacturer wants to reduce costs and capital investment in the production process, but its suppliers are unable to meet and provide their own ideas, facing the rising costs of products and materials. The difficult situation makes them have to find new partners who can provide comprehensive solutions and a team of performance analysis engineers.

What can we do for them?

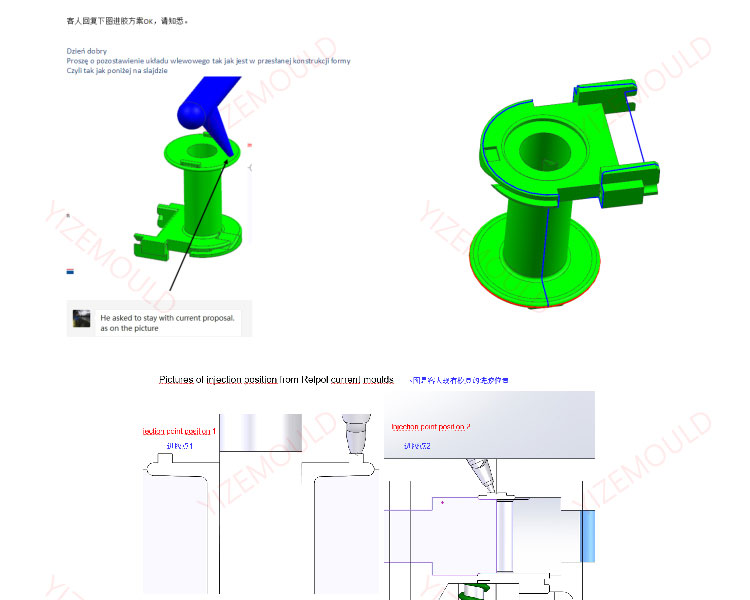

Our first cooperation is about the KORPUS CEWKI DC high precision plastic injection mold project. Among them, the problems we encountered are worth describing:" Do it need to change the position of the product inlet?" for the customer's requirements.

After the engineer analyzes the existing glue point, the original glue point closing is cut. After discussion, we believe that the best solution for the product’s glue inlet gate is the thickest position, which is finally recognized by the customer Our plan.

KORPUS CEWKI DC high-precision plastic injection mold and product information as below:

The material is the true color of PBT+30#GF.

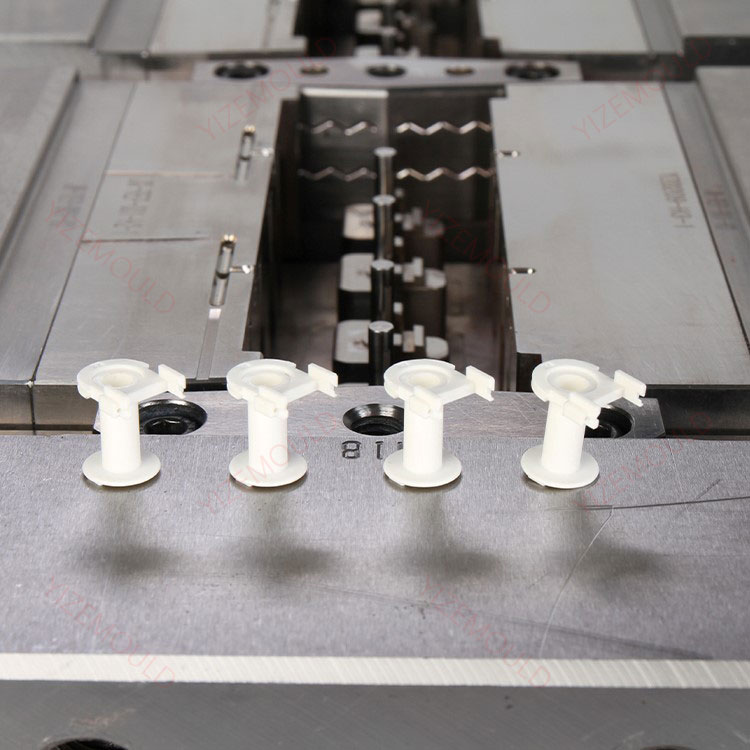

The customer's request our company provides them with one out of eight molds Meanwhile the shrinkage rate: 0.6%

Features of the product:

1. The part structure is ejection by force, the thickness of sleeve ejection is only 1.65mm.

2. To ensure the cooling time is 12s, we recommend using thimble alloy copper (HRC38-42) material. However, the customer disagrees. In the end, the inner needle of the alloy copper material should be HRC38-42 and the hardness of the mold parts should be HRC58-60.

3. The surface finish: the polish of cavity& core is SPI-B3

From high volume to low volume plastic injection production, we support you throughout your entire high precision plastic injection mold projectt!!16 years of experience 180 sets of equipment thermoplastics, special engineering plastics, focusing on the high-precision plastic injection mold, Connectors, Teflon, Medical mold molding parts and Mold spare parts.Welcome touch!