There are two Connector Mould Cavity number methods for injection molding, single cavity, and multi-cavity.

When should we choose multi-cavity and when should we choose a single cavity?

We will list our views below, hope we can communicate together!

1.multi-cavity molds will produce more products than single-cavity molds in the same time,

2. Shortening the delivery time

3. Ultimately lowering the price of production products.

4. The total cost of a multi-cavity mold will be lower than that of multiple single-cavity molds.

At present, the maximum number of cavities is 32. For more cavities to choose from, we can see more details on the injection mould product page

1. multi-cavity Connector Mould have stricter requirements for mold quality control.

2. multi-cavity molds must maintain the absolute perfection of each cavity before they can start work. One cavity has a problem, and the other cavities cannot be used.

3. In order to avoid more risks, the testing time of multi-cavity molds is longer than that of single-cavity molds

1. Single cavity molds are suitable for proofing

2. Single cavity molds are suitable for small batch production.

3. Single cavity molds can use multi-cavity molds for later mass production.

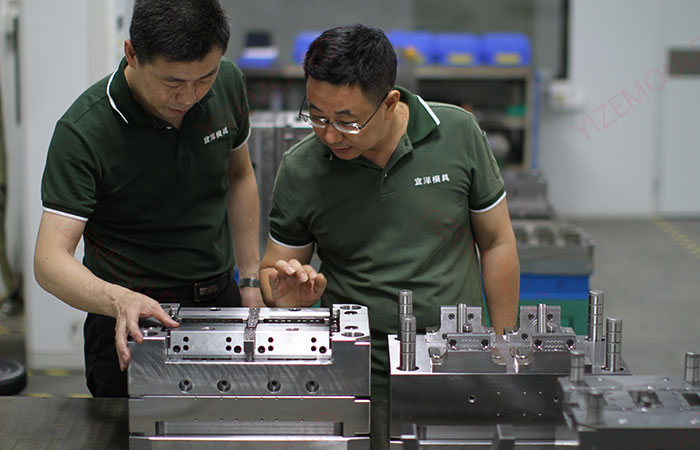

We have made relevant Connector Mould Cavity molds for Yazaki.

Injection Mould Cavity number single-cavity mold or a multi-cavity mold depends on the number of products produce 、certain period of time 、the cost advantage.

Let our injection molding experts advise you: Connector Mould Cavity number choose!

Our injection engineering team will provide customers with relevant suggestions:

1. Provide a free DFM report, through the preliminary simulation, comprehensively propose our plan for customer reference(We can check some case studies about the injection molding DFM)

2. Mold layout, we will submit our Connector Mould Cavity solutions regularly