In the plastic injection molding parts manufacture, we have to deal with Precision Plastic Parts Mould material plastics every day, but plastics are divided into many kinds.

Today we are mainly talking about the difference between PA66 and PP in plastic injection molding parts manufacture.

PA66 means that the natural color is cream yellow and black, and it is a semi-crystalline-crystalline material

The advantages of PA66 :

1. Has high fatigue strength and stiffness

2. Strong heat resistance

3. High wear resistance

4. Flame retardant: even if PA66 does not add flame retardant, the flame retardant grade reaches HB

The disadvantage of PA66 :

1. It is highly hygroscopic, and it is easy to produce bubbles and silver wires in the finished product.

2. Insufficient dimensional stability. If PA66 is not dried before processing, it is difficult to control the product size

PP refers to polypropylene, a colorless and translucent thermoplastic lightweight general-purpose plastic

The advantages of PP :

1. High wear resistance

2. Strong resistance to moisture absorption

3. High-temperature resistance of 100~120 degrees Celsius

The disadvantages of PP :

1. The light transmittance is not strong

2. Insufficient gloss

3. Weak rigidity

4. Higher melting point

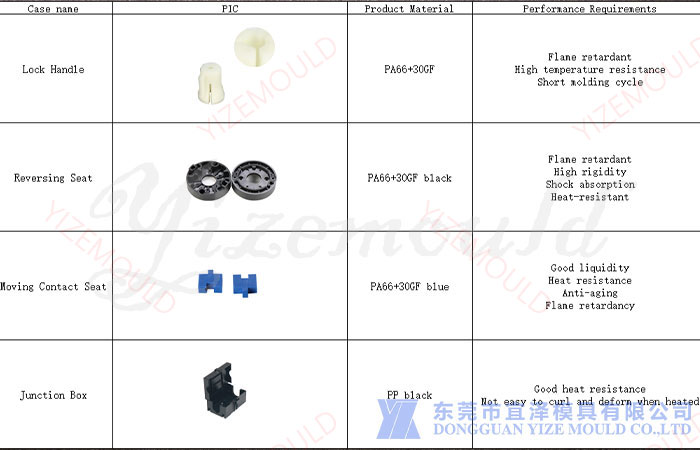

The following is a case table of our plastic injection molding parts manufacture's partial application of Precision Plastic Parts Mould material plastics: PA66 and PP

For more plastic injection molding parts products, please contat us!