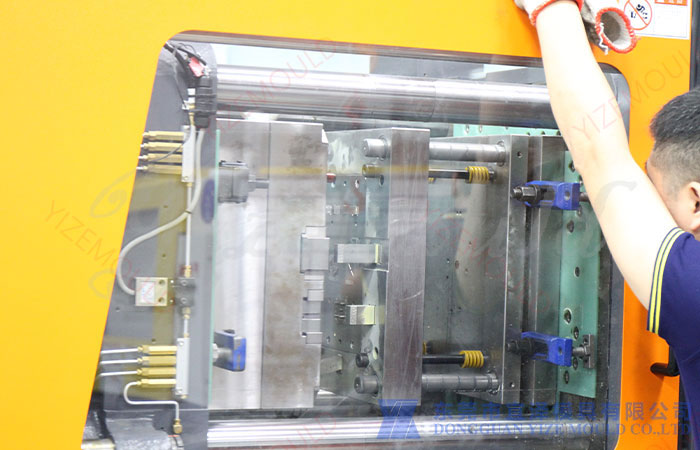

After the mold is produced, Yize will provide customers with injection molding assembly and mold trial services. The following are the 13 major taboos about the plastic injection molding parts process summarized by our injection molding engineers.

1. The plastic injection molding parts process and characteristics of the raw materials are not understood during production and test molds, resulting in incorrect mold temperature

2. The drying box and crusher were not cleaned up during production and test molds, resulting in mixing and wasting of raw materials

3. The raw materials are not properly marked in time, and they cannot be prepared in time during use, which results in work delays and wrong raw materials.

4. Failure to prepare raw material drying preparations in time during production, resulting in production delays

5. Unreasonable setting of molding parameters causes machine alarm

6. Inadequate protection around the machine, causing the plastic injection molding parts to fly randomly, affecting the surrounding 5S

7. Did not understand the mold structure before work, resulting in abnormal mold test

8. The molding process is unreasonable, resulting in damage to the product mucosa or mold

9. No abnormality of the mold during work was found to cause damage to the mold or workpiece

10. The nozzles and waste rubber blocks were not cleaned up in time, affecting the plastic injection molding parts workshop 5S

11. The machine is not cleaned up after the mold is changed, resulting in mixed products

12. After the mold trial is completed, the peripheral tools of the machine are not returned in time, and the cleaning is not timely, which affects plastic injection molding parts workshop 5S

13. Check whether the return protection device is installed to avoid compression molding

Yize Mould provides a one-stop overall solution from high-precision plastic injection mold to plastic injection molding parts on plastic injection molding parts process.

We insist on using stringent standards ahead of the industry to make quality products comparable to similar products in Japan, Europe, and the United States, but the manufacturing speed and cost-effectiveness far exceed those of Japan, Europe, and the United States.