How about surface treatment for high precision plastic injection molds? How does it work?

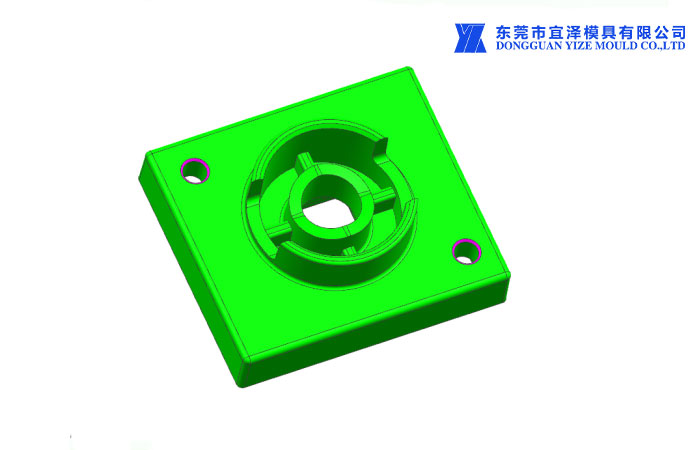

PC optical bracket of high precision plastic injection mold surface treatment case study

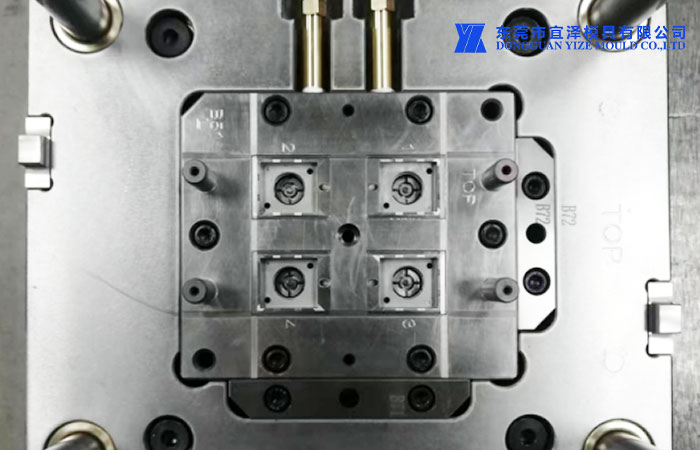

Number of mold cavities: 1*4

Customer Part Name: OPTICAL HOLDER

Product material: PC

Material Model: 121R

Colour: Black

Product net weight: 1.938g*4

Head weight: 2.687g

Estimated weight: 5kg

Machine model: 30T

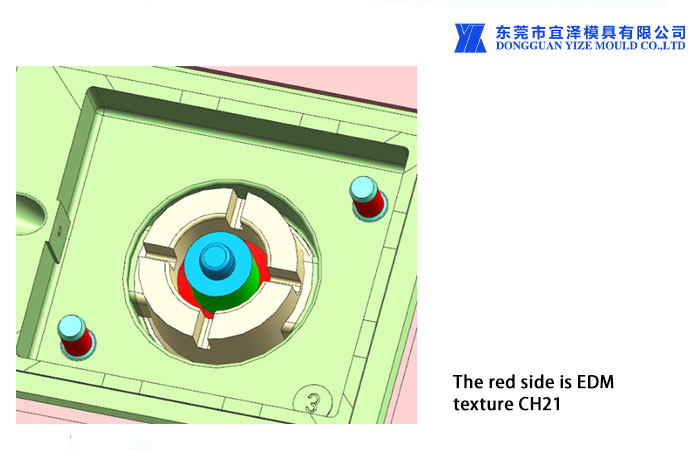

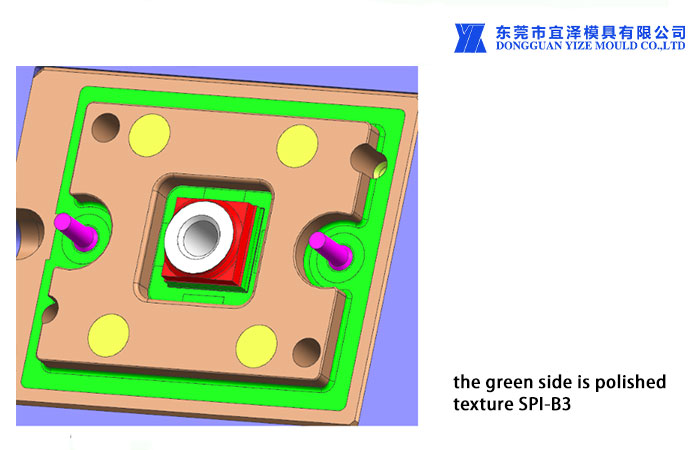

Customer request about high precision plastic injection mold surface treatment

The red side is EDM texture CH21, the green side is polished texture SPI-B3

Solution:

EDM (Electrical Discharge Machining), also known as spark erosion, uses graphite or copper electrodes placed in a water or oil electrolytic cell. When the electrode reaches the threshold current, it creates a spark on the tool wall. The target melted but was immediately quenched by the surrounding electrolyte. This causes thermal shock, which causes the metal to shatter into tiny particles, which are then washed away.

Spark corrosion works on both hard and soft metals and can produce very tight tolerances. It is ideal for making deep grooves, sharp reentrant corners, debossed lettering and other features that are difficult or impossible to machine traditionally. In addition, very fine and smooth surface finishes can be achieved, eliminating time-consuming and expensive manual polishing.

It is a standard in the United States for high precision plastic injection mold surface treatment finish. If it is steel, I know the effect of processing with 320 whetstone.

Attachment: International Standard Processing Method for Surface Roughness

Standard grade code Surface roughness Processing tool (method) Processing material and hardness requirements Photometric description

Coarse grinding grit size Fine grinding grit size Diamond paste polishing

SPI(A1) Ra0.005 S136 54HRC: Very high finish, mirror effect

SPI(A2) Ra0.01 DF-2 58HRC: Low finish, no sandpaper pattern

SPI(A3) Ra0.02 S136 300HB: The finish is one level lower, but there is no sandpaper pattern

SPI(B1) Ra0.05 No brightness: with slight 3000# sandpaper grain

SPI(B2) Ra0.1 No brightness: with slight 2000# sandpaper grain

SPI(B3) Ra0.2 No brightness: there is a slight 1000# sandpaper pattern, the direction of the processing marks cannot be distinguished

Along with the development of the mold industry, the performance requirements of the high precision plastic injection mold are increasing, and the life problem is becoming more and more profitable. Welcome to the challenge of accepting molds, the market will continue to develop.