PFA precision injection molding is an advanced technology in the field of plastics processing. As the applications of PFA are getting more and more, the demand for technological breakthroughs in PFA precision injection molding is getting more and more urgent. Compared with common plastics such as PC, PP, PE, etc., PFA has unique properties, which put forward higher requirements for processing technology and equipment. In spite of many challenges, with the wisdom of technicians and the efforts of workers, we successfully overcame the difficulties and realized the breakthrough of PFA precision injection molding.

The characteristics of PFA bring considerable challenges to precision injection molding. First of all, its shrinkage rate is much higher than that of traditional plastics, up to 9 times that of PC. This means that dimensional control becomes exceptionally critical during the injection molding process. To cope with this challenge, we use high-quality PFA raw materials, which are specially treated to effectively reduce shrinkage and improve the dimensional stability of the product.

In addition, PFA has poor fluidity, which increases the risk of product deformation. In order to solve this problem, we take the characteristics of PFA into full consideration when designing the molds, and by optimizing the structure of the molds, we reserve enough space for subsequent processing. This strategy effectively reduces the possibility of product deformation and improves product quality.

When performing PFA precision injection molding, the high temperature environment is extremely demanding on the equipment. To meet this condition, we have upgraded our injection molding equipment to improve its high-temperature resistance. This ensures that PFA will not be damaged due to high temperatures during processing and further improves product qualification rates.

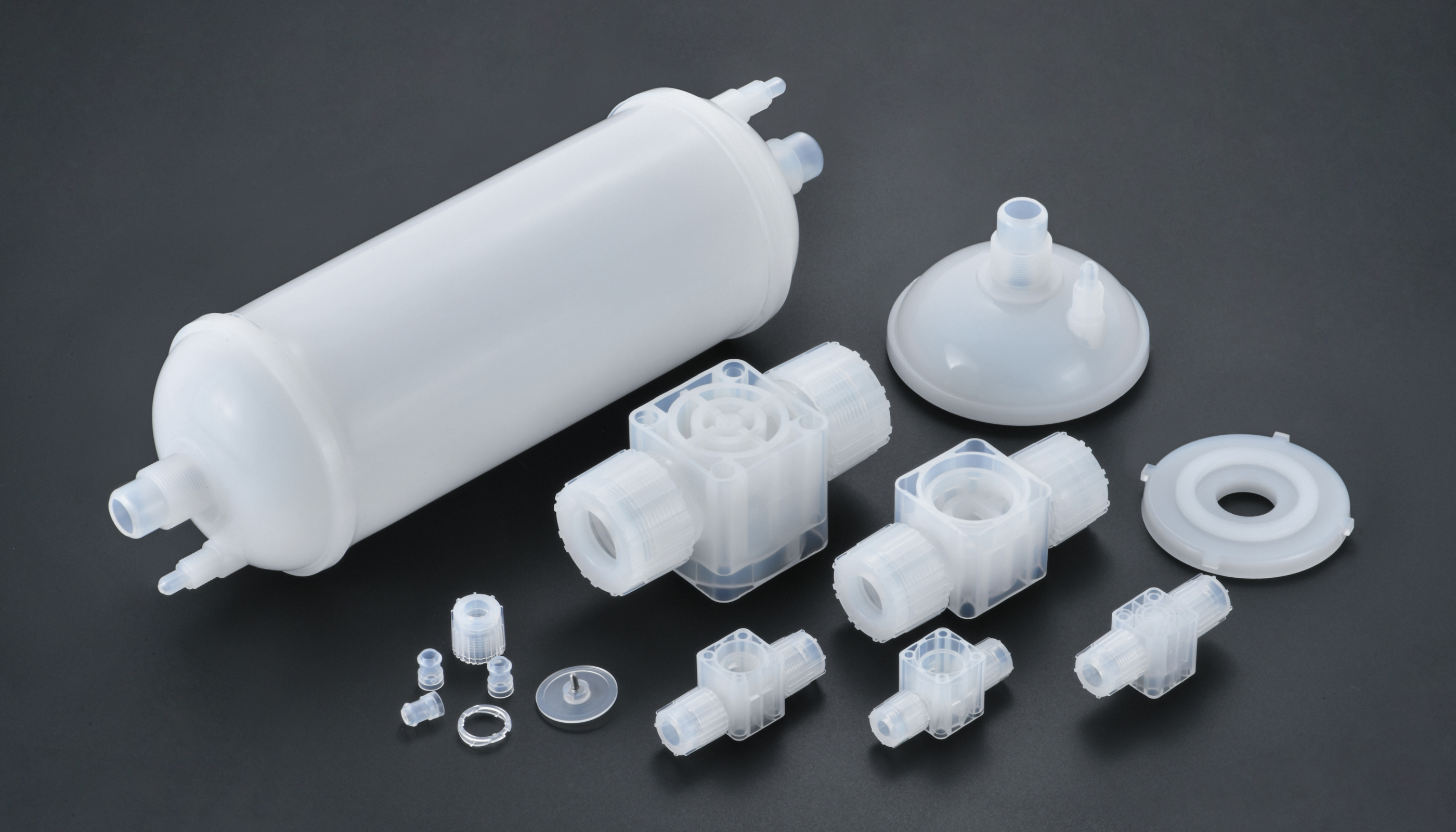

After overcoming these challenges, we have successfully controlled the injection molding tolerance of fluorine products to within ±0.05mm, reaching an industry-leading level. We have also succeeded in trial production of PFA fittings under our own brand KENNOS. This breakthrough not only reflects our strength in the field of precision injection molding, but also lays a solid foundation for future technological innovation.

The reason why we can make a technological breakthrough of PFA precision injection molding is not only because we have advanced machines and equipment and professional technicians, but also because our business philosophy is: in the pursuit of the material and spiritual well-being of all employees at the same time, to create value for our customers and make outstanding contributions to society. We integrate this philosophy into our daily business activities, and constantly polish our products and services with the spirit of craftsmanship, striving to provide every customer with the best quality products and the most attentive service.

If you are interested in our PFA products, or still have other questions to consult, you can contact us at [email protected] . We will be happy to serve you and look forward to cooperating with you.