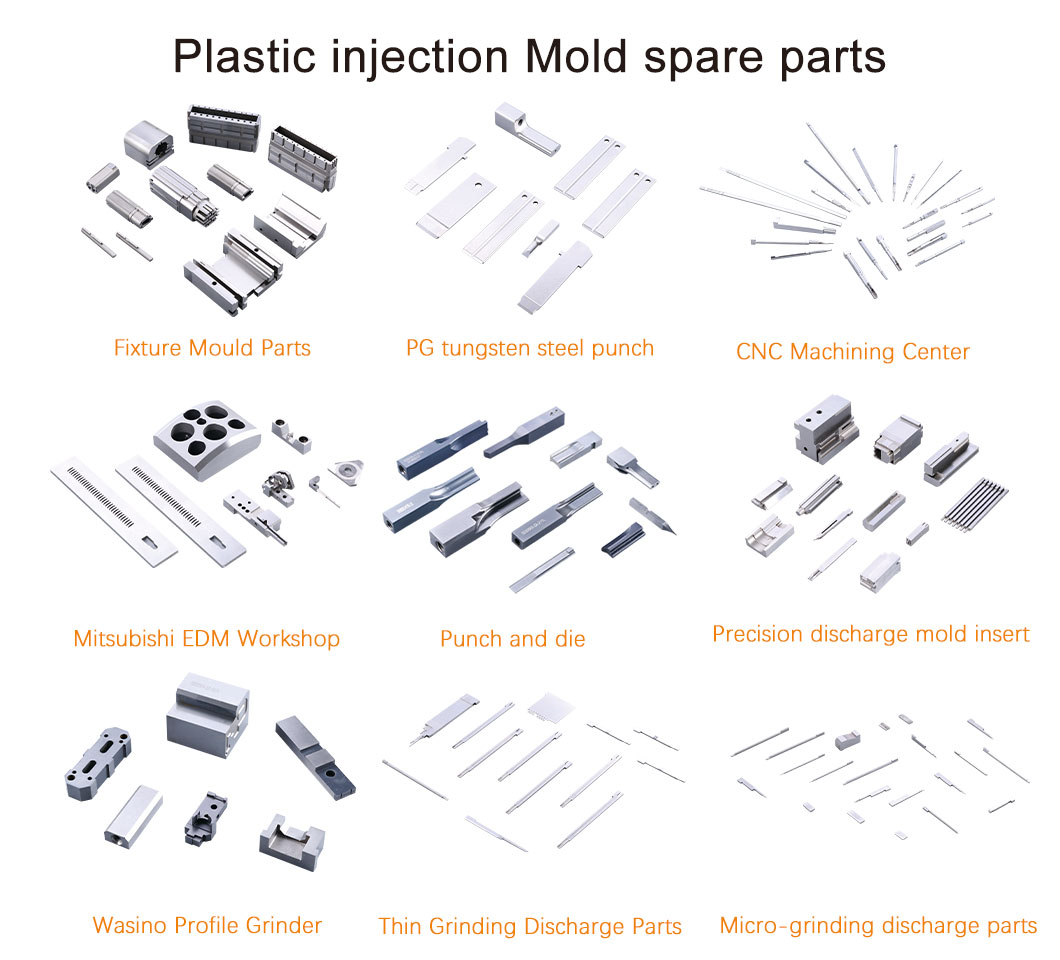

Product material:Japan (SKD11.SKD61.SKH51.S45C)

USA (AISA.D2.H13.P20.M2)

Germany (DIN.2379.2363.2344.2347)

ASSAB(Rigor.Stavax.Impax.Elmax.ASP23)

Hardness: 58-60 HRC

Grinding accuracy: 0.001mm

EDM Plastic injection Mold spare parts Starting from 1 part with a EDM/Wire Cut Precision within 0.005mm Free DFM reports provided.

| General Precision: 0.005mm | Dimensional Precision: ±0.001mm |

| Grinding precision within 0.001mm | Coordinate Precision: 0.001 |

| EDM/Wire Cut Precision within 0.005mm | Parallelism: ±0.002mm |

| EDM Angle clearance within R0.01 | Straightness: ±0.002mm |

| Straightness: ±0.002mm | Coaxiality: ±0.002mm |

| All Steel types available, special requests accommodated | Roundness: 0.0015mm |

| 7 Days Express Processing Service offered | Surface Roughness: Ra0.025 |

| MOQ 1 pcs Accepted | Surface Roughness (EDM) : Ra0.04 |

Q. Are you a trading company or manufacturer?

Yizemould are manufacturer Located in developing industrial city of Dongguan Guangdong China that Professional integrated injection Mold spare parts processing area

Q: How can I get a sample?

A: Customer can get a sample by sending 2D/3D/PDF drawing.

Q: What's your lead time?

A: 7-15 days normally, depends on the quantity and complexity of the components.

Q: What information should I provide to get a quotation?

A: Material, quantity, dimension, tolerance; CAD drawing will be best if convenient.

Q: What about after-sale service?

A: Spare parts which are non-man-made damaged will be offered a replacement for free within 90 days after shipment, and you can contact us any time if need help.

Q: How about your quality control?

A: 1. Every processing technician mastered the inspection skills in order to check each dimension during machining;

2. After the completion of processing, parts will be transferred to the QC department for full dimension inspection.

3. Double-check before packing to make sure no defective products will be released.

Q: Do you have the surface finishing capability?

A: Yes, and divided into the following sections

1. Grain surface treatment --- polishing, fire pattern, erosion, sandblasting

2. Electroplating treatment -- -nickel plating, zinc plating, chrome plating, titanium plating, chrome plating, flash chrome plating.

3. Nanocoatings - TIN, TICN, DLC, TIAIN, Crain, CrN