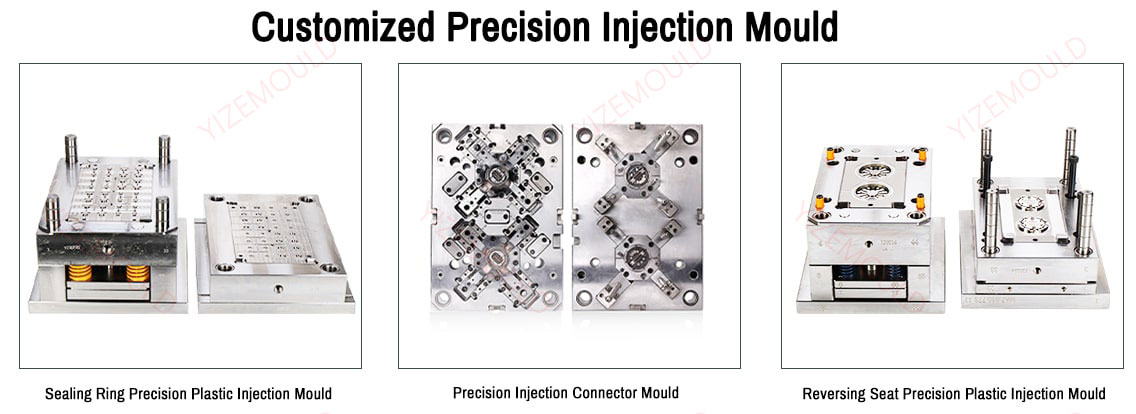

Mould base: LKM, HASCO, FUTABA, imitation DME, etc.

Mold life: 200,0000 times

Mold material: SKD61, PO613 S136 1.2343 S7 NAK80 etc.

Number of mold cavities: single-cavity, multi-cavity customized on demand

In close cooperation with our customer engineers, we have designed and produced connectors and cable assemblies with extremely tight tolerances for many of the largest electronics companies and manufacturers in the world.

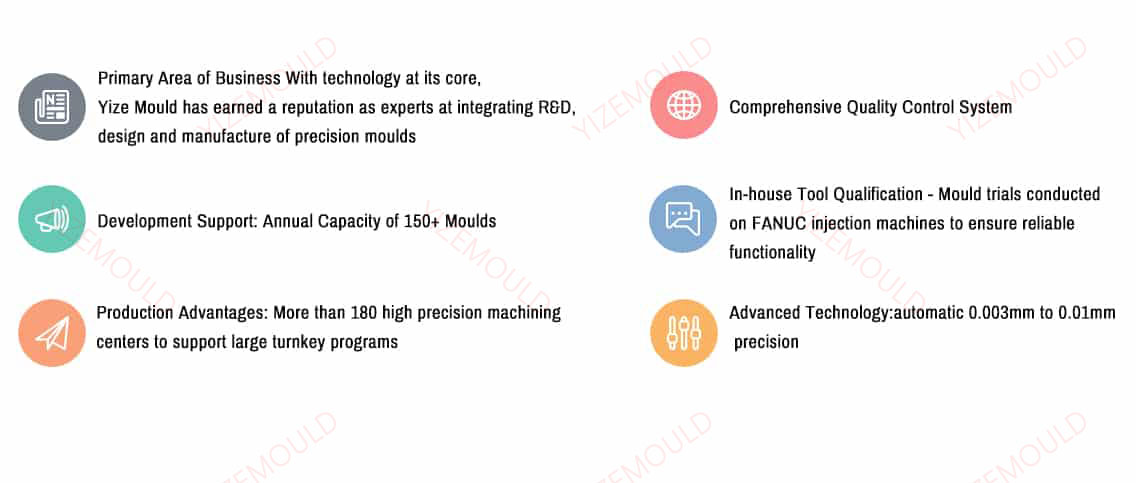

Regardless of whether you need a customized high precision mould, close tolerance mould components or a complete manufacturing program, Yize Mould has a solution for you!

Now let's get in touch to discuss how we can help with your project!

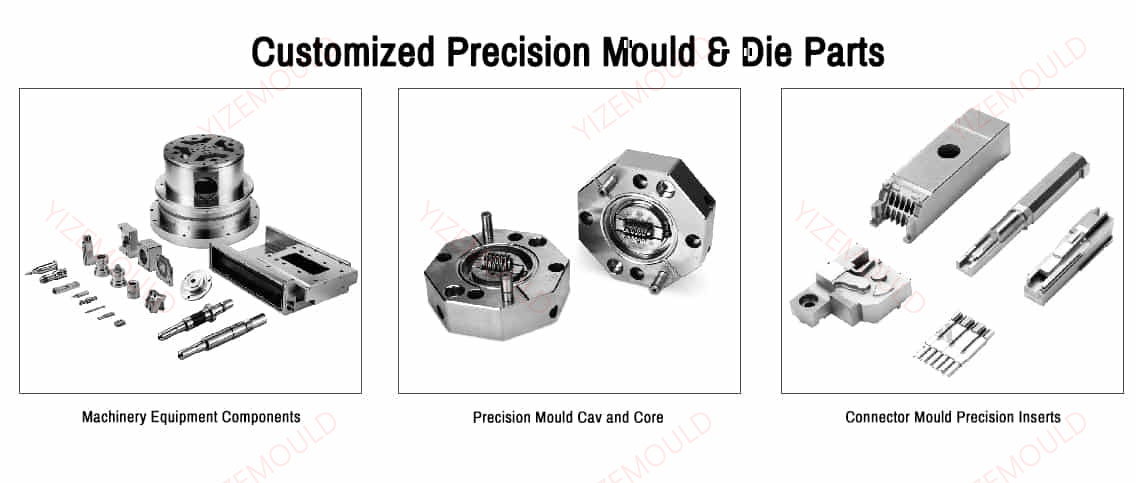

| General Precision: 0.005mm | Dimensional Precision: ±0.001mm |

| Grinding precision within 0.001mm | Coordinate Precision: 0.001 |

| EDM/Wire Cut Precision within 0.005mm | Parallelism: ±0.002mm |

| EDM Angle clearance within R0.01 | Straightness: ±0.002mm |

| Straightness: ±0.002mm | Coaxiality: ±0.002mm |

| All Steel types available, special requests accommodated | Roundness: 0.0015mm |

| 7 Days Express Processing Service offered | Surface Roughness: Ra0.025 |

| MOQ 1 pcs Accepted | Surface Roughness (EDM) : Ra0.04 |

In close cooperation with our customer engineers, we have designed and produced connectors and cable assemblies with extremely tight tolerances for many of the largest 、

electronics companies and manufacturers in the world.

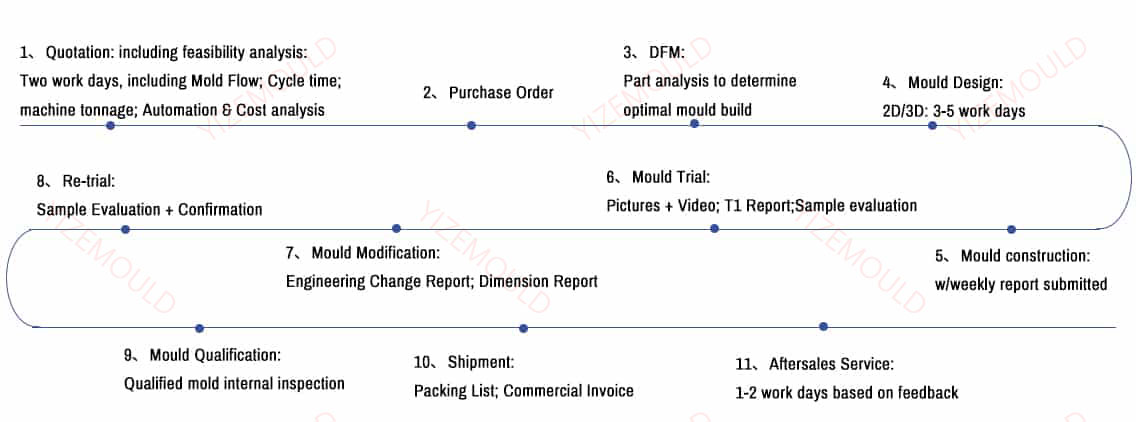

We have a simple step-by-step ordering process that can quickly analyze your needs. This allows us to provide you with the estimated duration of the order.

Producing World-class Products to Thrill Your Customers

Creating a quality product requires a team of experts bringing unique skills and knowledge; collaborating with your team to guarantee success.

Q. Are you a trading company or manufacturer?

We are manufacturer Located in developing industrial city of Dongguan Guangdong China.

Q: How can I get a sample?

A: Customer can get a sample by sending 2D/3D/PDF drawing.

UPS, OCS, EXPRESS, DHL, FEDEX are available for shipment.

Q: What's your lead time?

A: 7-15 days normally, depends on the quantity and complexity of the components.

Q: What information should I provide to get a quotation?

A: Material, quantity, dimension, tolerance; CAD drawing will be best if convenient.

Q: What about after-sale service?

A: Spare parts which are non-man-made damaged will be offered a replacement for free within 90 days after shipment, and you can contact us any time if need help.

Q: How about your quality control?

A: 1. Every processing technician mastered the inspection skills in order to check each dimension during machining;

2. After the completion of processing, parts will be transferred to the QC department for full dimension inspection.

3. Double-check before packing to make sure no defective products will be released.

Q: Do you have the surface finishing capability?

A: Yes, and divided into the following sections

1. Grain surface treatment --- polishing, fire pattern, erosion, sandblasting

2. Electroplating treatment -- -nickel plating, zinc plating, chrome plating, titanium plating, chrome plating, flash chrome plating.

3. Nanocoatings - TIN, TICN, DLC, TIAIN, Crain, CrN