Many clients ask us about the precision of plastic molds. In fact, this precision depends on the mold, production equipment, and technical requirements of the client. Generally, the precision of a single mold component can reach ±0.005mm, while the tolerance of a complete set of injection molds can be controlled within ±0.015mm. However, there are many variables affecting injection precision, such as product material, mold condition, injection molding machine model, and operator skill, which can all impact product tolerance. Therefore, our injection precision is typically controlled at a maximum of 0.02mm, and for materials with significant deformation like PFA, it can only reach 0.05mm.

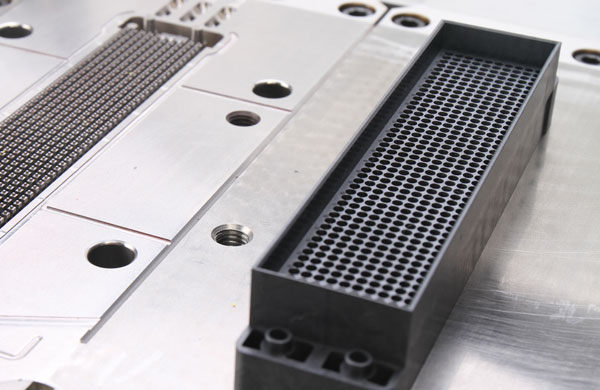

So, how do we manufacture such precise plastic molds? Let Yize reveal the secrets of manufacturing precision plastic molds. Yize molds utilize mold flow analysis to meet the needs of different product development and design. Through high-speed cutting (30000rpm), precision mirror EDM, high-precision wire cutting processes, combined with three-dimensional inspection equipment, we produce high-precision plastic molds.

Let Yize reveal the secrets of precision mold manufacturing to you:

A. We can manufacture various surface treatment specifications for molds, from general textures like hairline, thunder engraving patterns, water drop textures, and ripple textures, to various levels of polishing, mirror finishing, optical mirror finishing, glare mirror finishing, and electroforming mirror finishing.

B. High-speed cutting (30000rpm) can achieve near-mechanical polishing functionality, maintaining geometric precision and surface finish.

C. Precision mirror EDM can meet various complex geometric requirements. The electrodes produced can directly manufacture high-precision surfaces with mirror finishes and various patterns, combining aesthetic design requirements with precise dimensional requirements.

D. High-precision wire cutting processes allow many originally complex deburring tasks to be seamlessly joined through high-precision wire cutting, eliminating tedious and time-consuming EDM deburring work.

Dongguan Yize Mold Co., Ltd., established in 2007, is located in Dongguan, the manufacturing capital, with convenient transportation and logistics. It is a group enterprise engaged in precision mold design and manufacturing, as well as precision injection molding product production. The company specializes in automotive connector injection molding, special material (such as PEEK, LCP, PPSU, etc.) injection molding, precision injection molding parts, PFA fluorine product injection molding, mold components, tungsten carbide round piece processing, and other injection molding parts. We provide a complete set of solutions for product design, precision mold manufacturing, injection molding and assembly, and after-sales service.