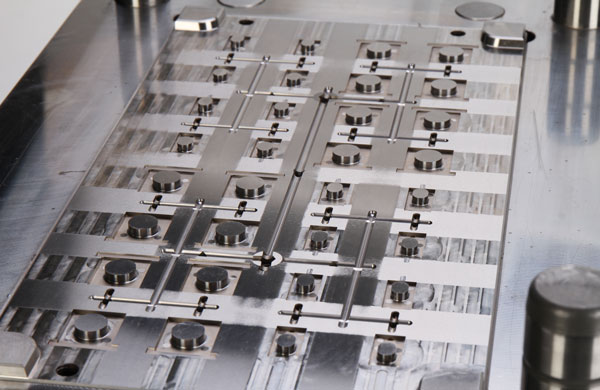

A tool that, under external force, shapes raw material into components with specific shapes and dimensions. It is widely used in blanking, die forging, cold heading, extrusion, powder metallurgy part pressing, pressure casting, as well as in the forming processes of engineering plastics, rubber, ceramics, and other products through compression or injection molding. Precision medical molds have specific contour or cavity shapes. Applying a contour shape with an edge can separate the raw material along the contour line (blanking). Applying the cavity shape can give the raw material the corresponding three-dimensional shape. A mold generally consists of two parts: a movable mold and a fixed mold (or a punch and a die), which can be separated or combined. When separated, the component is removed; when combined, the raw material is injected into the mold cavity for shaping. Molds are precision tools with complex shapes that withstand the expansion force of the raw material, requiring high structural strength, stiffness, surface hardness, surface roughness, and processing precision. The development level of mold production is one of the important indicators of mechanical manufacturing proficiency.

Dongguan Yize Mould Co., Ltd., established in 2007, is located in Dongguan, the manufacturing capital, with convenient transportation and logistics. It is a group enterprise engaged in precision mold design and manufacturing, as well as precision injection molding product production. The company specializes in automotive connector injection molding, special material (such as PEEK, LCP, PPSU, etc.) injection molding, precision injection molding parts, PFA fluorine product injection molding, mold components, tungsten carbide round piece processing, and other injection molding parts. We provide a complete set of solutions for product design, precision mold manufacturing, injection molding and assembly, and after-sales service.