Cracking, a common flaw in plastic products, stems from stress deformation, primarily caused by residual stress, external stress, and environmental factors.

(1) Residual Stress: The Hidden Culprit

Residual stress, often triggered by overfilling, improper ejection, and metal insert embedding, poses a challenge. Strategies to mitigate cracking due to overfilling include:

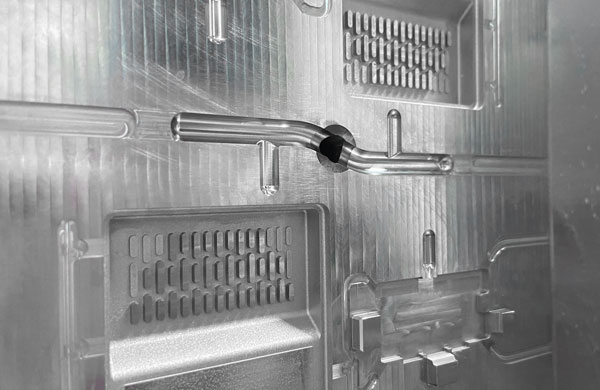

Adjusting gate strategies: Opt for multi-point, side, or handle-shaped gates to distribute stress.

Fine-tuning resin temperature: Increase resin temperature while ensuring no degradation, to reduce melt viscosity, enhance flow, and lower injection pressure.

Balancing mold temperature and injection speed: Adequately raise mold temperature; high injection speed can mitigate stress even at slightly lower temperatures.

Time control: Shorten injection and holding times, or employ segmented holding for better results.

Resin selection: Non-crystalline resins (e.g., AS, ABS, PMMA) are more prone to residual stress than crystalline ones; choose wisely.

Ejection issues, such as insufficient draft angles and rough mold surfaces, can lead to excessive force and cracking. Observing crack locations reveals the cause. Metal inserts, due to their vastly different thermal expansion coefficients from resins, are a potential time-delayed crack source. Select materials with similar coefficients or preheat inserts for prevention.

(2) External Stress: A Design Consideration

External stress, particularly stress concentration due to improper design, is another major cause of cracking. Sharp corners require careful design to avoid excessive stress.

(3) Environmental Factors: Invisible Erosion

Chemical agents, moisture-induced hydrolysis, and excessive use of recycled materials can degrade properties and induce cracking. Strengthening material management, controlling recycled material ratios, and implementing effective moisture prevention measures are crucial.

In summary, addressing the crack dilemma in injection molding involves meticulous process parameter adjustments, rational product design, and strict environmental factor control. Only then can we ensure the flawless presentation of plastic products, making each piece a testament to quality.