In the journey of product development, prototypes, rapid molds, and steel molds are the three essential tools for designers and engineers. They not only bear the responsibility of verifying designs and optimizing functions but also directly relate to the final production efficiency and quality of products. Today, let us delve into the mysteries of these three, exploring their definitions, primary applications, manufacturing processes, and respective advantages and disadvantages.

Prototype: The Bridge Between Creativity and Reality

Definition Interpretation: A prototype, also known as a sample or model, is the first physical model meticulously crafted based on product design blueprints. It serves as the embodiment of a designer's thoughts, providing intuitive evidence for design verification and adjustment.

Core Value: Before mold development, prototypes play a crucial role. They not only verify the product's appearance design, structural rationality, and functional realization but also facilitate effective communication between design teams and clients, laying a solid foundation for subsequent mass production. Through prototypes, design flaws can be exposed early, significantly reducing development risks and accelerating product launch processes.

Process Essence: Prototype production combines the fine craftsmanship of handworkers with the precision and efficiency of modern CNC technology. From CAD design to CAM processing, every step embodies the pursuit of perfection, ensuring that prototypes can accurately reflect design intentions while quickly responding to design changes.

Pros & Cons Analysis: Prototypes are renowned for their intuitiveness and flexibility, but their production costs and time are relatively high, and their accuracy is limited by materials and processes. Nevertheless, they remain an indispensable part of product development, providing valuable input for design optimization and decision-making.

Rapid Mold: The Embodiment of Speed and Efficiency

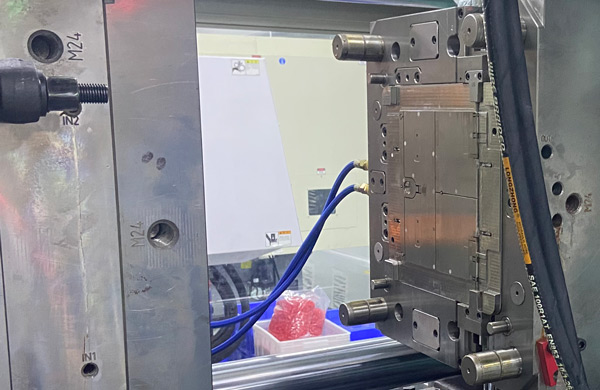

Definition Interpretation: A rapid mold, also known as a prototype mold or soft mold, is an efficient and economical tool for producing parts in batches. Leveraging advanced technology, it achieves rapid conversion from design to production, significantly shortening product development cycles.

Application Scenarios: In the prototype testing stage of new product development, rapid molds play a pivotal role. They not only help verify the actual performance of components but also test production parameters, providing valuable feedback for engineers and designers to facilitate continuous design optimization.

Process Highlights: Rapid mold production cleverly combines standardized mold bases with customized inserts, utilizing rapidly processed materials such as aluminum or soft steel, significantly reducing additional processes, lowering mold-making costs, and increasing mold-making speed.

Pros & Cons Overview: Rapid molds are favored for their short cycles, low costs, and ease of promotion, particularly suitable for short-term production needs. However, their service life is relatively limited, unable to meet the demands of long-term, high-intensity production.

Steel Mold: The Epitome of Precision and Durability

Definition Elucidation: A steel mold, as a precision tool for shaping metal materials, is widely used in various fields such as automobiles, machinery, ships, electrical appliances, and daily necessities. Its diverse types, including stamping molds, die-casting molds, injection molds, etc., each bear different production tasks.

Application Value: With their excellent hardness, precision, and long service life, steel molds have become the preferred choice for manufacturing high-precision, high-quality products. They can withstand high-intensity, high-temperature, and high-pressure working environments, ensuring the accuracy of product shapes and dimensions.

Process Essence: The production of steel molds is a complex systematic project, encompassing mold design, material selection, CNC processing, heat treatment, precision assembly, and debugging, among other steps. Each step requires careful planning to ensure the performance and quality of the mold.

Pros & Cons Analysis: Steel molds have won widespread praise for their unmatched precision, stability, and durability. However, their manufacturing process is complex, costly, and time-consuming. Despite this, for enterprises pursuing long-term, large-scale production, steel molds remain an indispensable production tool.