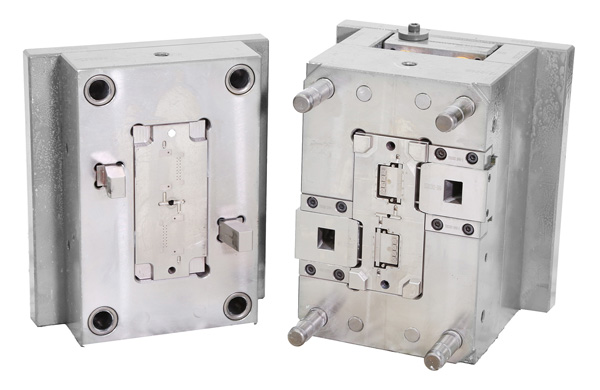

In the injection molding process, surface wear failure of injection molded parts, as a common form of mold failure, refers to the condition where the mold cannot continue to ensure product quality due to severe wear on the mold cavity surface after a period of use. This phenomenon is directly related to production efficiency and cost control, so it is crucial to have a deep understanding of its causes and countermeasures.

Detailed Description of Manifestations

The specific manifestations of surface wear failure in injection molded parts include the following: a significant increase in the surface roughness of the mold cavity, leading to a decrease in the surface finish of the product; the appearance of scuffed areas on the inner walls of the mold cavity, affecting the product's appearance and dimensional accuracy; and, more seriously, excessive wear of the mold cavity causing the dimensions of the injection molded parts to exceed the allowable deviation range, directly impacting the product's qualification rate and functionality.

In-depth Analysis of Influencing Factors

Material Friction Characteristics: During the injection molding process, especially when molding materials contain hard fillers such as glass fibers, these hard particles slide across the mold surface, generating intense scraping action that accelerates mold wear.

Effect of Corrosive Gases: Plastic and its fillers may release volatile corrosive gases at high temperatures during the melting process. These gases can react chemically with the mold material, further exacerbating surface corrosion and wear of the mold.

Improvement Measures and Practical Strategies

Selection of Mold Materials: Choosing mold materials with high wear resistance and corrosion resistance is a fundamental and effective measure. For example, using steel containing special alloying elements can significantly enhance the mold's wear resistance and service life.

Innovation in Surface Treatment Techniques: Professional surface treatment of the mold cavity surface, such as nitriding, chromium plating, or the application of advanced coating technologies, can not only increase surface hardness but also form a protective layer that effectively resists wear and corrosion, extending the mold's service life.

In summary, while surface wear failure in injection molded parts is inevitable, scientifically and reasonably selecting mold materials, optimizing the molding process, and strengthening mold maintenance can significantly slow down the wear rate, improve production efficiency, and reduce production costs. For the injection molding industry, continuous attention to technological innovation and material research and development is key to addressing this challenge and enhancing competitiveness.