Today let's talk to you about the Connector Mould supplier of the new case -Precision Connector Mould case study--FCI connector housing molding die

As the Connector Mould supplier, we will do our best and offer support to our customers when they face the challenge.

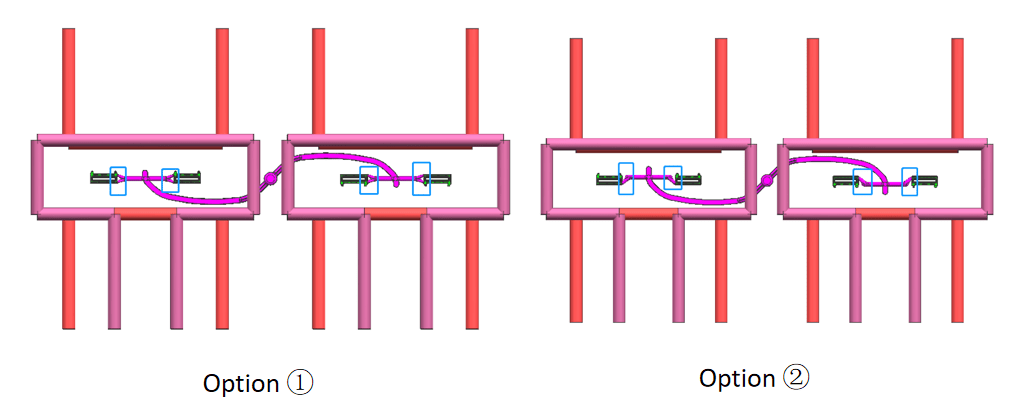

Which way to choose the gate?

Yize Connector Mould supplier offers an engineering team with DFM, which two glue feeding methods through for customers to choose.

We can see from the following two moving pictures that in DFM, we should pay attention to the problems of deformation, filling, pressure holding, shrinkage, cycle, etc.

Combine with our suggestion and client truly demand practical.

The final choice of latent glue feeding method

The advantage

(1) The inlet gate is generally on the inner surface or side concealed part of the plastic part, which does not affect the appearance of the product.

(2) After the product is formed, it will be automatically broken with the plastic part when it is ejected. Therefore, it is easy to realize production automation.

(3) Since the latent gate can be set on the ribs and pillars that are not visible on the surface of the product, it will not leave spray marks and air lines on the surface of the product during molding.

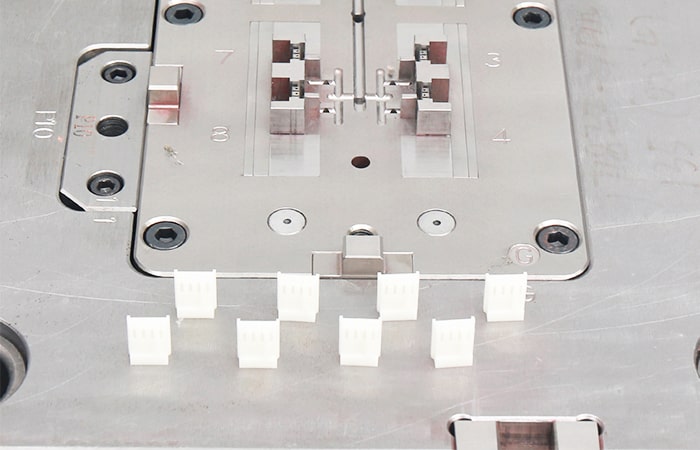

There are detail about connector housing and mold according to the Connector Mould supplier case study

Connector housing material: LCP E130i, 30% GF BLOCK

Connector housing size is: 5.49X12.7X9.9

Connector housing weight: 0.31g

Runner: cold runner

Core/Cavity Plate Steel: 8407ESR

Core/Cavity Inserts Steel: XW 10/SKD12

The mold cavity number of the mold is 1*8

The mold size is 300X350X331

Providing customers with a cost-effective Precision Connector Mould solution is Connector Mould supplier focus, and we will work hard to solve any design or production-related problems you face with the skills needed to face more complex challenges.