we are focused on pay attention to solving the high-precision plastic injection mold problems, such as this high precision plastic injection mold manufacture case study, we break the difficulty to the fixed contact piece of aviation

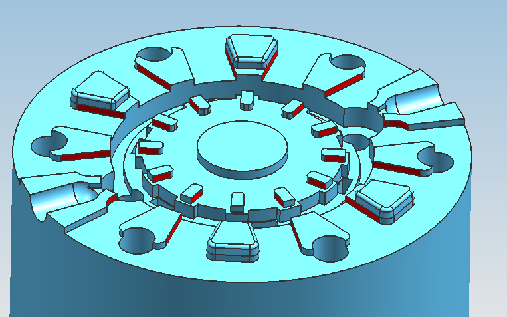

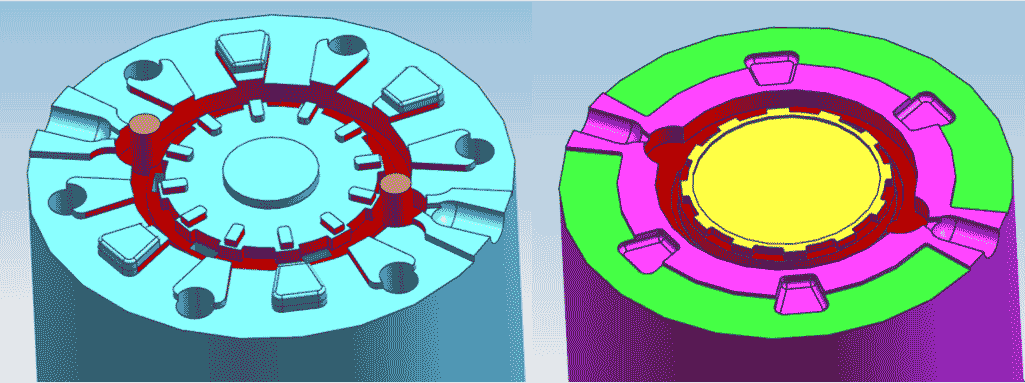

High precision plastic injection mold manufacture has developed a project for aerospace-related to aviation fixed contact Injection mold case study--Technical requirements for fixed contact B:

The fixed contact piece is a key part of electrical components. It rides on a pivotal position in electrical components. Once a defect occurs, it will cause poor contact. Therefore, the external dimensions and bending angle of the parts are required to be very high. The matching plastic parts should also have standards.

he aviation fixed contact piece injection mold case study: Technical difficulty requirements

1. The film should be flat without burrs and deformation

2. Use Cu/Ep.Ni4Au1hd.At plating

3. The root clear angle of the red area of the rear mold insert reaches Rmax0.03

4. The red face area of the front and rear mold inserts uses 1000# sandpaper, and all sharp corners are guaranteed not to collapse.

Product material: WH-9100F

Mold material: S45C

Number of holes: 1*2

We received them in good condition after service. we hope that our products can escort their safety and continue to succeed.

We are currently looking for more cooperative high precision plastic injection mold opportunities. If you have any problem, We are very happy to have the opportunity to cooperate with military industry companies to help them turn their ideas into reality.