Connector mold is one of our company's strong businesses. The following case sharing is an introduction to the Precision Connector Mould front mold in the automotive wiring harness connector example provided by our company for customers:

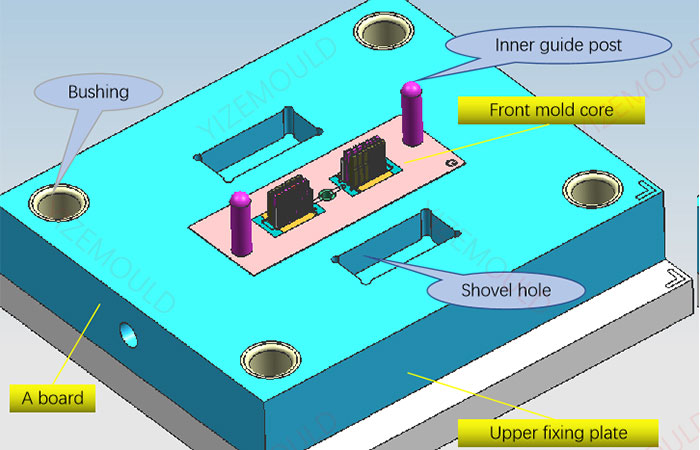

1. The upper fixing plate and A plate of the front mold are generally No. 45 or No. 55 steel, and the other parts are alloy steel.

2. The front mold core is the core part of the mold, and most of the product accuracy is guaranteed by the processing accuracy of the mold core

3. The hole of the mold core in the middle of the A-plate and the shovel hole requires high precision, which is the most basic guarantee for the front mold, the rear mold, and the alignment.

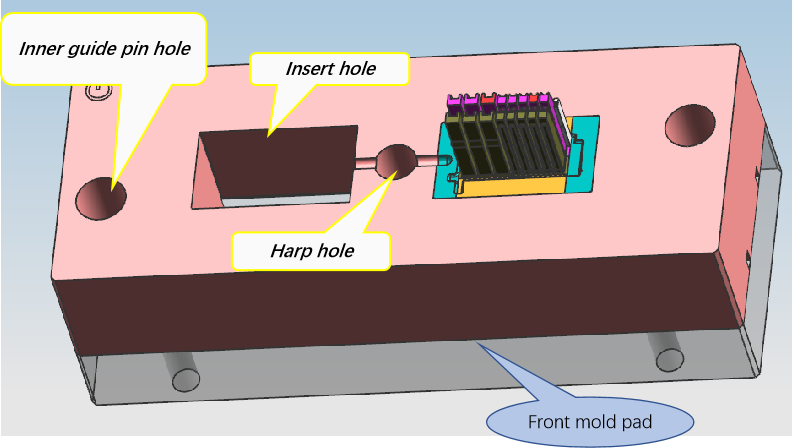

1. The right angle of the die core is guaranteed (within 0.005), and the verticality of all fine holes is guaranteed within 0.002

2. The inner guide pinhole is processed according to +0/+0.002, the insert hole is processed according to +0/0.005, and the nozzle hole is processed according to +0/+0.01. The position of the inner guide pinhole and the insert hole is 0.002

3. When machining, leave a margin for the shape. After the line is cut thick, the CNC will then fine-tune the right angle (leave the margin), finish cutting, and finally, the shape is in place (grabbing the hole position)

Precision Connector Mould front mold · Processing key points: Milling machine, CNC, and wire cutting are all processed on four sides. The thread of the milling machine must always be tested for verticality and effective depth, and the water hole must not be too deep (measured with standard screws)

Only by ensuring the quality of Precision Connector Mould can the accuracy of precision connector mold products be ensured. We has the professional equipment and an excellent team of engineers to provide you with a one-stop mold product experience!