The mold core refers to the precision parts used for the key operation of the center part of the mold. The general structure of the mold core is extremely complex, the processing is very difficult, the cost is high, and the labor expenditure for manufacturing often exceeds the material itself. The choice of mold core material is directly related to the cost of the mold and the service life of the mold.

because the choice of material quality directly affects the service life and cost price of the whole set of molds in the later period.If the demand for the product is large and the mold core is made of poor quality materials, the mold may be scrapped before the production demand is reached, and the mold needs to be re-developed, which will ultimately affect the company's production efficiency, and the secondary processing will increase the cost of the mold.

If the demand for the product is small, choose good quality materials to make the mold core, although the good use of the mold in the production process is ensured, but the production capacity of the mold has not been fully utilized, the production demand has been exceeded, and the company's cost is excessive. , Is also a waste

Common mold core materials include P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136, etc.

According to the customer's demand for hardening the mold core, the following materials can be selected: 2344, 8407, SKD11, SKD61, etc.

Accuracy requirements: ±0.005mm

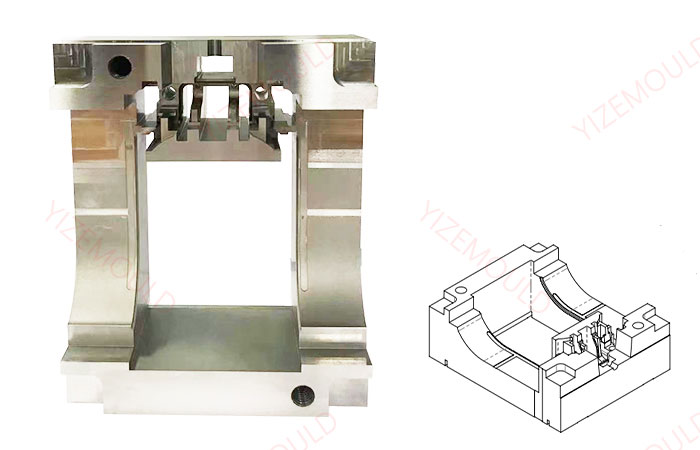

We can see the mold core we provide to our customers from the picture below:

Characteristics of mold core material:

Among them, one of the materials of the mold core is introduced: S-STAR

S-STAR is a kind of plastic mold steel with super mirror surface, high hardness, and corrosion resistance formed by special processing and melting. It has good corrosion processing and electrical discharge processing. It is suitable for high-precision case medical equipment molds. Plastic mold

Through CNC precision processing, computer gong processing, MC processing, slow-moving wire, WEDM, and other complex program processing, the final mold core processing is completed

For many years, through the excellent quality delivery service, it is deeply trusted by customers at home and abroad. If there is a need for precision Mould Core, please contact us, we will provide the best service