In the plastic molding process, the temperature of Teflon plastic injection mold is very important. The mold temperature will directly affect the Aberration of Precision Plastic Parts Mould, filling, orientation, molding cycle, and quality of the plastic, and the color difference of the precision plastic product injection is prone to problems.

What are the results at different temperature of Teflon plastic injection mold?

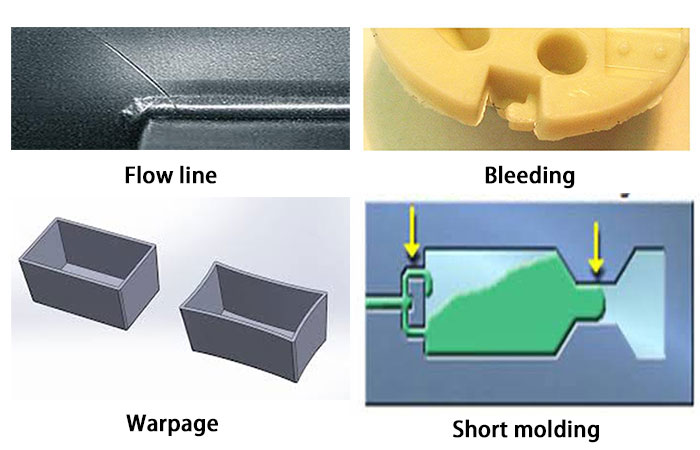

1. the temperature of Teflon plastic injection mold is too high, the molding shrinks, the deformation rate of the plastic part after demolding is large, and it is also easy to cause flashing and mucous film

2. the temperature of Teflon plastic injection mold is too low, the melt fluidity is poor, the contour of the plastic part is not clear, and the surface will have obvious defects such as silver threads or flow lines.

3. When the temperature of Teflon plastic injection mold is uneven, the temperature difference between the core and the cavity is too large, the injection molded part shrinks unevenly, resulting in warpage and deformation, which will affect the shape and dimensional accuracy of the injection molded part

Temperature control is a test of experience and technology for operating engineers. Yize Mould is equipped with a professional team to control the entire process of injection molding to the product. At the same time, it unifies the FANUC injection molding machine imported from Japan to provide Teflon plastic injection mold services throughout the process and strives to achieve true success. Good products that customers are satisfied and assured.