The reasonable Precision Plastic Parts Mould system of precision plastic products plays a vital role in the performance, structure, size, internal and external quality of injection molded parts, and is closely related to the plastic consumed by the plastic parts and the production efficiency.

Focus on the cavity layout, and use a balanced layout as much as possible to set up a balanced runner. The cavity layout and the gate position should be symmetrical to prevent the mold from being eccentrically loaded and causing flashing, etc., and try to make the cavity arrangement as compact as possible. Reduce the overall size of the mold. At the same time, the heat and pressure loss should be small, and the flow of the gating system should be kept as short as possible, the cross-sectional size should be increased as much as possible, the bending should be minimized, and the surface roughness should be reduced.

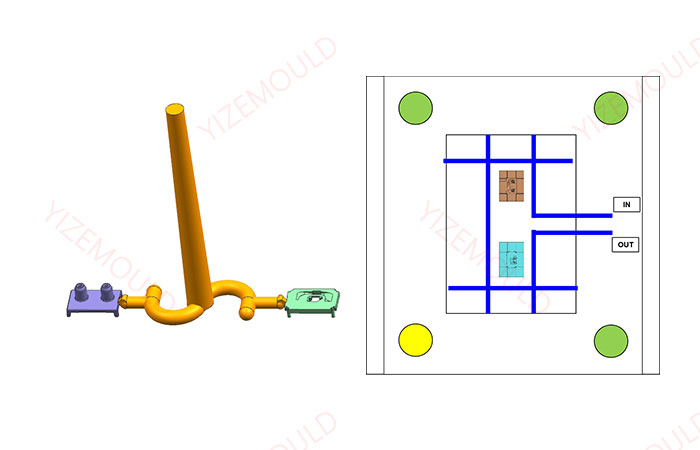

As shown in the figure below, both the cavity layout and the gate position in the figure are striving to be symmetrical

As far as possible, the plastic melt enters the deep and corners of each cavity at the same time, that is, the runners, and the balanced layout is used as much as possible.

Plastic consumption is small. Under the premise that each cavity is filled, the volume of the pouring system should be as small as possible to reduce the consumption of plastic.

Precision Plastic Parts Mould system of precision plastic products should be able to collect the "cold material" with lower temperature to prevent it from entering the cavity and affecting the quality of the injection molded parts.

Prevent defects in injection molded parts, avoid insufficient filling of the melt or porosity, shrinkage, residual stress, warping deformation or excessive dimensional deviation of the injection molded parts, as well as deformation and displacement of the stamping position of the plastic flow, resulting in various poor molding phenomena

Pay attention to the temperature of the precision plastic mold and control the appearance quality of the injection molded parts. According to the size, shape and technical requirements of the injection molded parts, it can be removed. It is convenient to trim the gate and the gate marks are not damaged or Aberration of Precision Plastic Parts Mould.

As far as possible, the injection molded parts should not be processed or post-processed less, the molding period is short, and the efficiency is high

The above are the seven points of attention and the principles to follow for the Precision Plastic Parts Mould system.