With more than 16 years of experience in the injection molding industry, equipped with a class 100,000 clean room, as a manufacturer of injection molding products, we provide Medical plastic injection mold project, custom injection molding from 30 tons to 300 tons.

Mainly provide mold and injection molding services for nuclear magnetic resonance (NMR) imaging devices, biochemical analyzers, color ultrasonic diagnostic instruments, X-ray tomography scanners, etc.

High efficiency and good control, from parts to final assembly, are 100% manufactured in the factory, which translates into better quality products and more competitive injection molding prices through investment in equipment and quality control systems. This is also the most important factor in our ability to deliver quality injection molded parts on time.

The Medical plastic injection mold project Process

Medical plastic Injection molding process sequence: mold clamping - filling - pressure holding - cooling - mold opening & demolding

Step 1 Clamping - Take care that the raw material is dried to the proper moisture content, mixed with the pigment or masterbatch colorant, according to the International Bypass Color Chart

Step 2 Filling - Pour the dry pellets into the hopper of the molding machine. A reciprocating screw inside the machine barrel is used to transport these pellets into the die while heating them

Step 3 Pressure Hold - Inside the barrel, the pellets are mixed and heated until fully melted, forming a liquid resin The heated mold closes automatically, and the resin is injected into the mold cavity through a gate under enormous pressure

Step 4 Cooling – The mold cools for a short time to solidify the internal parts

Step 5 Mold Opening & Demoulding – The mold is opened and the part is ejected to start a new cycle

| Medical plastic injection mold Services | Medical plastic injection mold Materials |

|

|

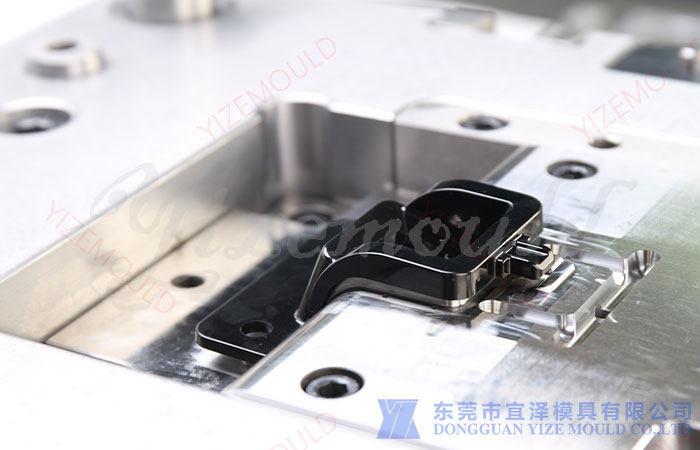

Yize mould specializes in high precision plastic injection mold thermoforming and manufacturing. We offer services to meet any of your engineering needs, including:

√ Class 100000 Clean Room

√ Quality Control

√ Low & High Volume Manufacturing

√ Competitive Price

√ Reliability and Stability

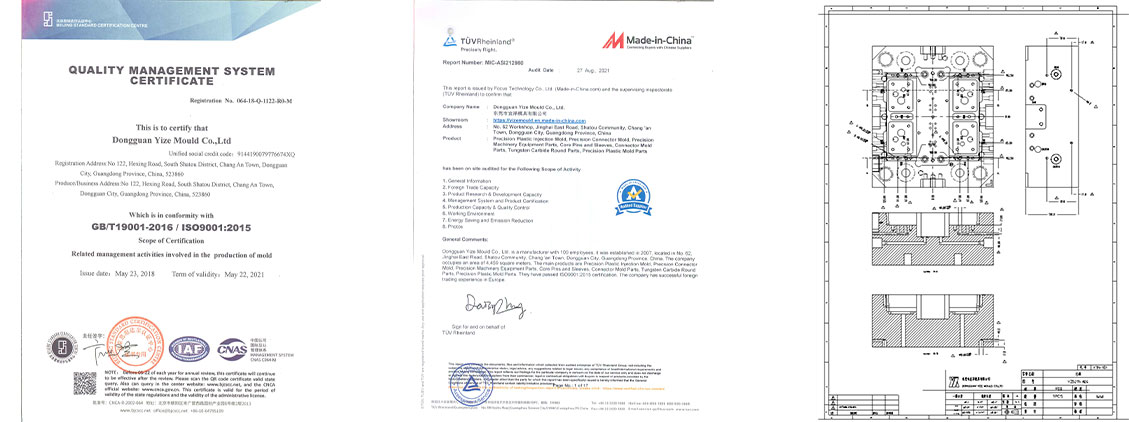

| DFM - Design for Manufacturing | Guaranteed accuracy | ISO 9001:2015 & TÜV Rheinland |

Leave a message or send a contact (email and phone) for instant guaranteed quotes and automatic DfM feedback. | 125 employees Class 10000 cleanroom for medical plastic injection mold.precision medical plastic injection mold accuracy 0.003mm, injection molding 0.02mm. | A general quality management system applies to all of our manufacturing services. Because every job is important! |

Supported By

Supported ByIn close cooperation with our customer engineers, we have designed and produced connectors and cable assemblies with extremely tight tolerances for many of the largest 、electronics companies and manufacturers in the world.

Design ready?

Upload your information for a free, instant quote Get an instant quote