1 . Discuss cold runner and hot runner

We will recommend the use of hot runners for Medical plastic injection mold customer.

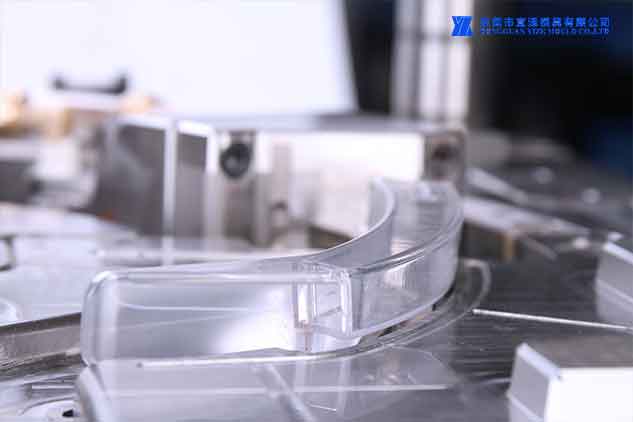

2 . Medical plastic injection molds Typical products include:

Infusion and infusion components

injection system

Connector

syringe

Blood collection products

3 . Mold material

In terms of materials, injection molds are also divided into soft molds and hard molds. Soft mold generally uses P-20 pre-soft steel, some outdated areas use carbon steel above 45, and the production capacity is generally about 50,000 times. ;

The hard die is made of hot work die steel such as H-13 (manganese steel) or 420 (stainless steel plate).

4 . Lifetime Warranty

We serve spare parts for Medical plastic injection mold customer during their service life

Guaranteed refurbishment during overhaul

Standard components available and in stock

5 . whole mold life cycle

The whole life cycle of the mold includes the whole process of mold design, processing, mold trial/repair, mold use, and mold scrapping

6 . Quality assurance of mold material

Our company has passed ISO 9001 quality management system. At the same time, it is equipped with a 100,000-level production injection molding workshop.

7 . price

It is mainly composed of mold material fee + design fee + processing fee + injection mold processing fee + modification fee + packaging and transportation fee

(1) Cost of mold material

Usually, we can choose the following materials: silicon-aluminum alloy, zinc-based alloy, aluminum alloy, zinc alloy, cast iron, bronze, etc. According to the choice, the quality and price of the product are also different, usually, the price is around 2000 RMB.

(2) Medical plastic injection mold design cost

For a professional design department, it takes 5 days to design a product in the company, and the salary ranges from 6,000 RMB to 8,000 RMB. The design fee is about 2,000 RMB even if the salary is calculated. If you find an outside designer, it usually doesn't include modifications. It is estimated that the design cost is more than 2000 RMB

(3) Mold processing cost

Mold processing needs to be processed with special equipment, such as CNC equipment, slow wire cutting equipment, and subsequent secondary element testing. Special processing needs to purchase special processing equipment, etc. The estimated cost is 10000-15000RMB, and the quotation is based on the difficulty of the mold.

(4) Injection mold processing: mold trial cost + injection test

Anyone who is engaged in the mold processing industry knows that molds cannot be made overnight. After the mold is processed, it must be sent to the customer to try the mold. The plastic casing made after each trial needs to be tried directly by the customer. Medical plastic injection mold customer put forward suggestions for rectification after use. Modify the mold, plastic, or plastic problems, modify the manufacturing process according to customer requirements. Often, the mold needs to be modified once or twice to get the job done. Try the mold two to three times, and the modification cost is about 2,000 RMB.

8. After-sales service and procedures

Guaranteed 200w life, as long as it is within the warranty period, we can maintain and clean the mold to ensure normal operation. Of course, the mold can also be shipped to the customer's country for production

9.Major maintenance cost of mold--create mold file

(1) Establish a complete set of usage records when each set of molds enters the factory, which is an important basis for ensuring future maintenance.

(2) List the wearing parts in the mold, and prepare the accessories in advance, such as thimbles, cores, and the minimum inventory of wearing parts, so as not to delay production due to insufficient preparation.

(3) If the mold with the cylinder core pulling machine is attached, the quick-change joint should be installed as soon as possible, which greatly shortens the time for the die-casting operator to load and unload the mold.

10 . Company strength, production capacity

11. Online access to the facility via video