Professional plastic injection molding parts material --PET plastic is one of engineering plastics. Engineering plastics have excellent comprehensive properties, high rigidity, small creep, high mechanical strength, good heat resistance, and good electrical insulation, and can be used for a long time in harsh chemical and physical environments. It can be used as an engineering structural material instead of metal. Thermoplastics have strong plasticity and excellent properties, and PET plastics are widely used.

Professional plastic injection molding parts material --PET plastic has excellent heat resistance, weather resistance, electrical properties, rigidity and strength. However, sometimes PET plastics have characteristics and defects, so PET plastics need to be reinforced.

The following table summarizes the Professional plastic injection molding parts material --Enhancement PET's four properties

| Specific Gravity Properties | Standard | Condition | Unit | Value |

|---|---|---|---|---|

| ISO 1183-1 | 23℃ | glcm3 | 1.27+0.03 | 1.27+0.03 |

| Mold Shrinkage | ISO 2577 | Cold mold, 48 hrs | % | 1.6-2.0 |

| Moisture Absorption | ISO 62 | 23 °C; 50 %RH | % | ≤0.3 |

| Mechanical Properties Properties | Standard | Condition | Unit | Value |

| Tensile Strength | ISO 527-2 | 5mm/min | Mpa | 52 |

| Elongation at Break | ISO 527-2 | 5mm/min | % | >15 |

| Flexural Strength | ISO 178 | 2mm/min | Mpa | 80 |

| Flexural Modulus | ISO 178 | 2mm/min | Mpa | 2100-2400 |

| lzod lmpact,Notched | ISO 62 | 23℃ | KJ/m2 | 6-10 |

| Thermal Properties Properties | Standard | Condition | Unit | Value |

| Melting Point | ISO 75-2 | 23℃ | ℃ | 220-240 |

| Heat Deflection Temperature | ISO 75-2 | 1.8 Mpa | ℃ | 60-70 |

| Flammability | UL94 | 1.6 mm | HB | |

| Electrical Properties Properties | Standard | Condition | Unit | Value |

| Comparative Tracking lndex | lEC 60112 | 23℃ | V | 600 |

| Volume Resistivity | IEC 60093 | 23℃ | Ω-cm | ≥1016 |

Flame-retardant modified and alloyed, which can significantly improve its heat resistance, modulus, toughness, dimensional stability and flame retardancy. Reinforced and toughened grade, reinforced low warpage grade, reinforced flame retardant, low warpage reinforced flame retardant, color stable reinforced flame retardant, high light reinforced flame retardant, halogen-free flame retardant and other series.

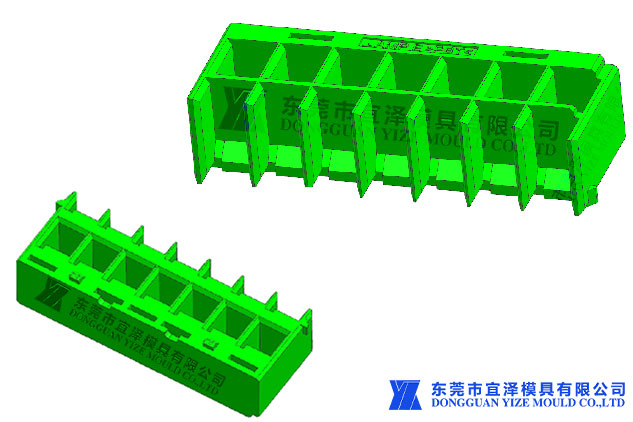

The picture above is a case of the PBT modified reinforced plastic we provided to TE connectivity.

We can analyze products specifically for customers,plastic injection molding parts material PBT is widely used in electronic components such as connectors, micro switches, capacitor casings, functional components such as keyboards and telephones of office equipment, automotive electronic components and charging guns for electric vehicles, and medical equipment, building materials, precision machinery and many other products that are close to our daily life.