Design standard Custom Medical plastic injection mold material selection principles:

The first point: the selection of materials must meet its use function in the mold;

The second point: Under the premise of meeting the first point, consider the cost factor and the mold type to select the appropriate material.

The following are Custom Medical plastic injection mold that standardized on different mold parts and deal with different precision requirements.

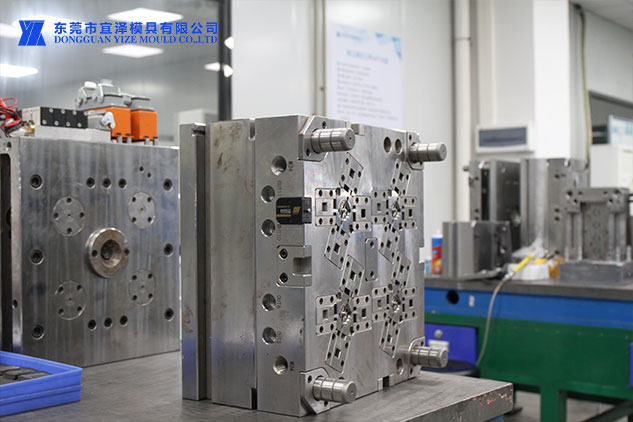

Custom Medical plastic injection mold using is mainly divided into four parts: Moldbase, Insert bolck, Insert , Slide Component

Moldbase:

(1). Cavity plate & core plate

Common materials: P20, 618HH, 718HH

Use hardness: N/A;

When the precision of the template is very high due to product factors, it can be used: M310, RAMAX, using hardness: N/A

(2). Core back plate & ejector back plate

Common materials: P20,

Use hardness: N/A;

Use when there are certain performance requirements: 618HH, 718HH,

Use hardness: N/A.

(3). Top & bottom insulation plate

Common materials: GLASS FIBBLE,

Use hardness: N/A;

(4). Other templates except (1) (2) & (3), such as Top & bottom insulation plate, Ejector plate, support bolck, etc.

Common material: S50C, use hardness: N/A;

Use when there are certain performance requirements: P20, use hardness: N/A.

Insert block:

(1). Insert block.

Common materials: 1.2083,

Use hardness: 52-54HRC;

When the performance requirements are high, it can be used: M310, STAVAX,

Use hardness: 52-54HRC

(2). Insert Back Plate

Common materials: 1.2083,

Use hardness: 52-54HRC;

Can be used when performance requirements are not high: 8402

Use hardness: 50-52HRC.

Insert :

(1). Insert Participate in product forming.

Common materials for common requirements: CALMAX,

Use hardness: 54-56HRC;

The workpiece is a slender type that is expected to be easily broken in production or has an Insert designed for insertion.

Commonly used: VIKING, W360,

Use Hardness: 56-58HRC,

For higher requirements or use: K390,

Use hardness: 60-62HRC

(2). Insert that does not participate in product molding.

Common materials: 8402

Use hardness: 50-52HRC;

Component:

(1). Mould Component

1) LocatIon Ring

Commonly used: S50C,

Use hardness: N/A;

2) Sprue Bush

Commonly used: SKD61,

Use hardness: 48-52HRC;

3) Support Pillar

Commonly used: S50C, 618,

Use hardness: N/A;

4) Stopper

Commonly used: S50C,

Use hardness: N/A;

(2). Slide Component

1) Slide Cam Hold

Commonly used: XW-10,

Use hardness: 58-60HRC;

2)Angle Cam

Commonly used: XW-10 (56-58HRC), or use: 8402 (50-52HRC);

3) Guide Rall & center Guide

Commonly used: XW-10 (56-58HRC), or use: 8402 (50-52HRC);

4) Pressure Pad

Commonly used: XW-10 (56-58HRC), or use: 8402 (50-52RC);

5) Wear Plate

Commonly used: XW-10 (56-58HRC), or use: 8402 (50-52HRC);

6) Cover Plate

Commonly used: 8402 (50-52HRC);

Material usage principle: parts that have a moving relationship with each other must use different materials;

If the same material is required, reduce the consumable replacement parts by 2HRC.

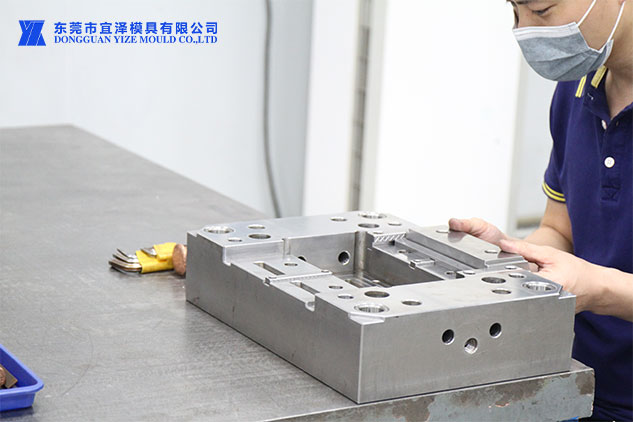

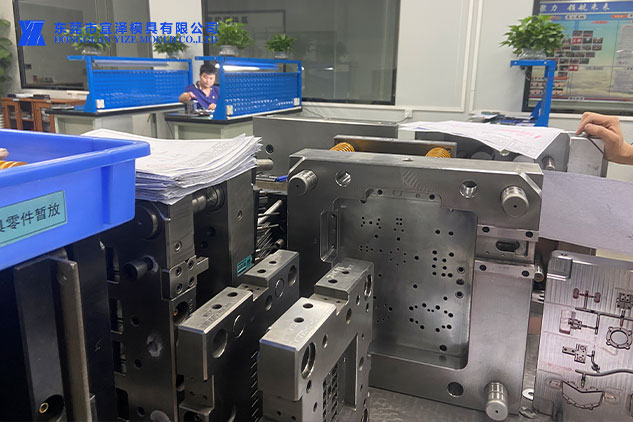

Yize mold is specialized in Medical plastic injection mold production with 180 sets of production equipment for 16 years, we are a world-leading thermoformed of highly aesthetic, complex medical device mold and products in the Medical plastic injection mold industry. We focus on manufacturing small precision, multi-part enclosures for the medical device industry.

we pay attention to offering the One-stop Solution design, engineering, manufacturing, assembly of Medical plastic injection mold. To seek high precision and control medical injection mold quality and molding quantity, we set up from 30ton to 150ton professional plastic injection machine workshop.

Yize engineer team's diverse experience and knowledge enable the development and manufacturing of advanced medical devices. and design to create customizable solutions for each of our clients.

Precision mold design and manufacture and mold parts processing, precision mold accuracy 0.003mm, injection tolerance 0.02mm. Not only provide the Medical plastic injection mold, but also we gain breaking areas of others.

Main precision: precision connector mould, precision medical mould, precision Teflon mould, precision plastic mould.