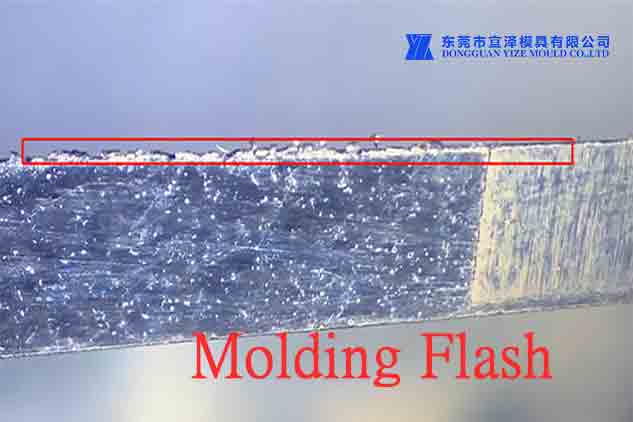

Molding Flash also known as flashing, overflowing, flashing, etc., mostly occurs at the point and place of the mold.

Different Raw material for plastic injection molding parts have different physical properties, and the overflow value is also different.

(1) If the viscosity of the plastic is too high or too low, flash may appear

Plastics with low viscosity, such as nylon, polyethylene, polypropylene, etc., should increase the clamping force; plastics with strong water absorption or water-sensitive plastics will greatly reduce the flow viscosity at high temperatures and increase the possibility of flashing. These plastics must be thoroughly dried; plastics with too much recycled content will also decrease in viscosity, and if necessary, the retained components should be replenished. If the viscosity of the plastic is too high, the flow resistance will increase, and a large back pressure will increase the cavity pressure, resulting in insufficient clamping force and flashing.

(2) When the particle size of raw material for plastic injection molding parts is not uniform, the feeding amount will vary, and the parts will be dissatisfied or flashed.

The following are the overrun values of our commonly used connector materials:

LCP material is 0.0015mm

PA66 material is 0.006-0.008mm

PEEK material is 0.008mm

PPSU material is 0.0005mm

PBT material is 0.008mm

Generally, plastic injection molding parts defects the locations where flash is likely to occur are:

The parting surface of the mold, the sliding part of the slider, the gap of the insert, the hole of the ejector, etc.

If the overflow is not solved in time, Raw material for plastic injection molding parts will further expand, so that the imprinting mold will form a partial collapse, causing permanent damage. The overflow of the gap of the insert and the hole of the ejector pin will also cause the product to be stuck on the mold and affect the demoulding.