Customer Profile: It is a company in the electronics industry, so the anti-static measures required for Plastic injection molding parts components PEEK electronic product

Static electricity has great damage and influence on electronic products. Circuits are quite sensitive to electrostatic high voltage. When a person or object with static electricity touches these components, electrostatic discharge will occur, resulting in damage to components or abnormal operation. Therefore, prevent static electricity. It is the key that the electronics industry cannot ignore.

Plastic injection molding parts Name: Standardized Lower Contact Floating Plate M

Plastic injection molding parts components material: Peek anti-static

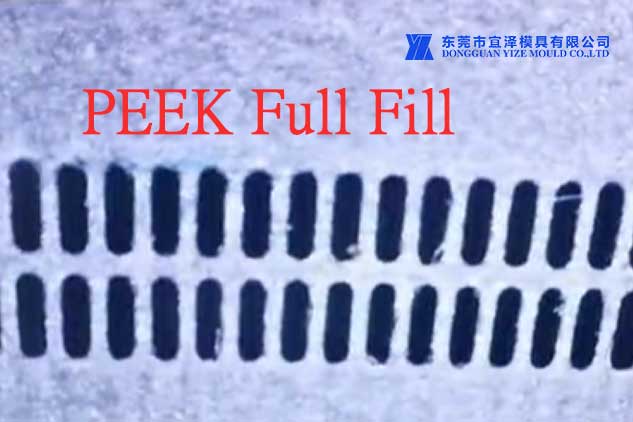

Plastic injection molding parts components Difficulties: Filling Dissatisfaction and Surface Resistance Anti-static Requirements

The net weight of the product : 0.886g*2

Peek engineering plastic material is characterized by fast crystallization and slow flow rate, which is easy to cause the phenomenon of unsatisfactory product filling.

We can see that the pins of PEEK products are not filled and the surface of the product is uneven by comparing with qualified plastic injection molding parts components.

There are several reasons for this:

1. The physical temperature of PEEK is not reached, and the injection temperature can be appropriately increased

2. There are additives in the PEEK material itself

3. The product itself is too thick and it is not easy to fill it completely. The product can be re-evaluated by adjusting the shape of the product

4. The injection pressure is small and the holding pressure is not enough. The injection machine debugging personnel should appropriately increase the injection pressure and increase the holding time.

5. In view of the small flow channel of the mold itself, it is obvious that we expand the mold flow channel to facilitate the smooth entry of PEEK plastic into the cavity

This product is different from ordinary PEEK. It needs to meet the electrostatic value standard required by the customer. The customer's requirement for the surface resistance of the product is to reach the sixth power of 10 to the eighth power of ten.

According to customer requirements, we have special test equipment.