PEI (polyether) has strong high temperature stability, toughness and strength, and is often used to make high temperature and heat resistant devices. At the same time PEI precision injection molding will have high injection temperature, injection molding process is complex, product performance is not stable and other difficulties. High requirements for equipment, process control and operators. So today, the appropriate mold to explain the attention of PEI injection molding processing.

1. Material drying: the drying equipment must be able to reach the temperature of at least 120℃ and. The drying system shall BE ABLE TO MAINTAIN THE RECOMMENDED DRYING TIME in a continuous operation, USUALLY 6 hours under the conditions described above.

2. Process control and monitoring: the precision injection molding process should be controlled by screw speed and position, not by pressure and time control. This ensures that injection rate and filling time are controlled.

3. Shutdown and cleaning: after the completion of precision injection molding operation, the use of thermal performance of more than 370℃ suitable cleaning material, no plastic left in the molding machine cylinder.

4. Injection speed: increase the injection speed as much as possible without causing embrittlement.

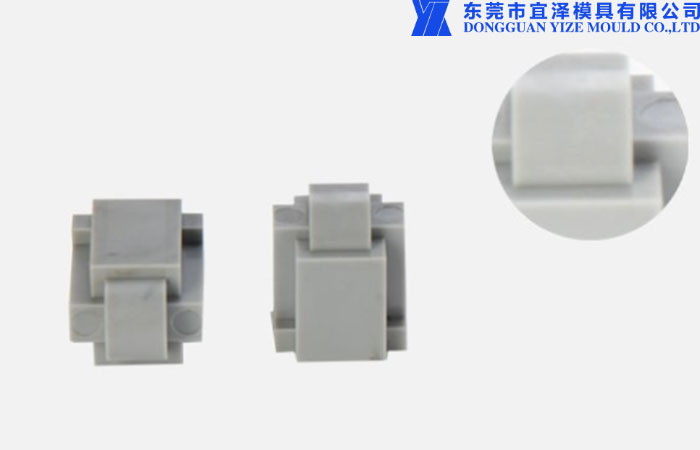

plastic injection molding parts-- PEI

Yize mold is located in the "Chinese mold town" known as Dongguan Chang 'an Town, China, fifteen years, Yize mold focus on "mold design and manufacturing, precision plastic mold manufacturing,high precision plastic injection"