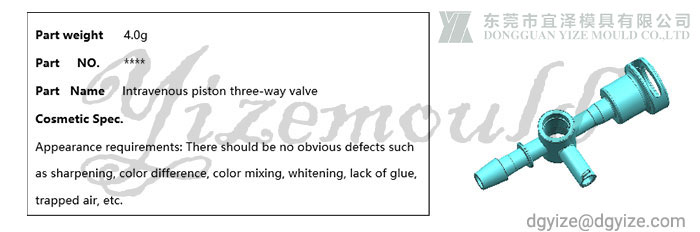

Medical plastic injection mold device products not only need to guarantee usability but also need a solid structure and a beautiful appearance.

The three joints of the three-way valve are respectively communicated with the needle seat of the blood transfusion device, the needle seat of the blood anticoagulation device and the venipuncture and cannula through the medical rubber hose.

At Yize Mould, we have medical plastic injection mold device equipment for our customers. This project highlights our breakthrough in medical plastic injection mold devices while guaranteeing close tolerance injection molding, which equates to cost savings over the entire product life cycle.

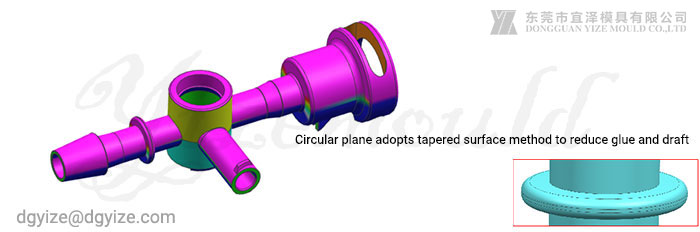

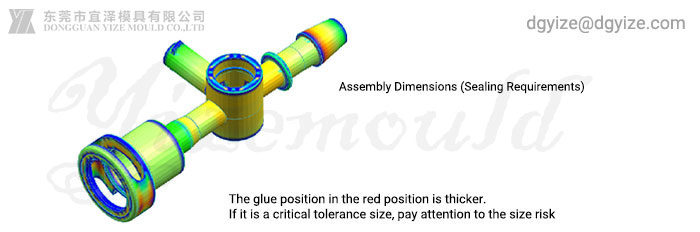

The product wall thickness refers to the glue level of the part. How to use UG to analyze the product wall thickness? After getting a model, before preparing to medical plastic injection mold device design, it is necessary to analyze the wall thickness first to see if the wall thickness is uniform, find its uneven position, so as to make adjustments, so as to avoid the product being caused by the wall thickness in the life of the product. defective products

The glue position in the red position is thicker. If it is a critical tolerance size, pay attention to the size risk

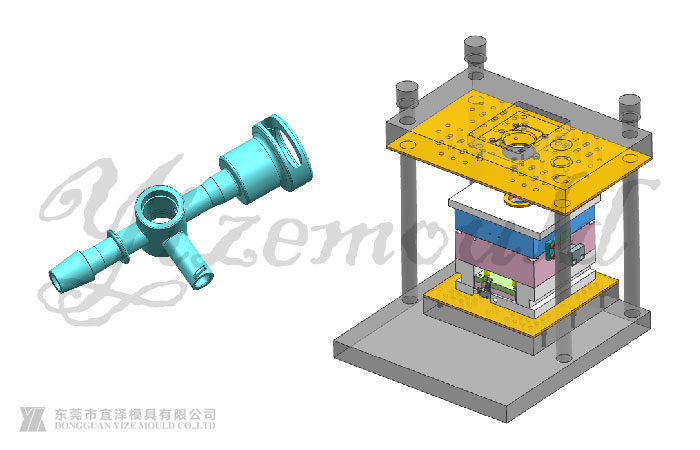

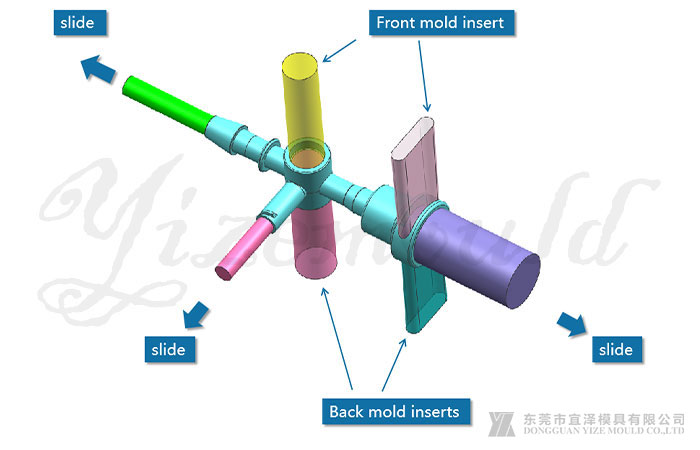

medical plastic injection mold device Product construckture Analysis

Product raw material selection, product design (such as product structure, functional conformity, mold making, and product injection feasibility analysis)

1.polish

2. Thin Fire Texture

3. Texture

4. plating

5.Sand Blasting

Fill analysis predicts the flow of thermoplastic polymers within the mold during the filling phase. The analysis calculates the flow front incrementally past the part from the injection location. Flow continues until the speed pressure switch point

This joint is not as strong as uninterrupted flow. Since the flow fronts can merge together and continue to flow through the cavity, there is a greater chance of compressing this area, thereby increasing its strength.

Fill analysis predicts the flow of thermoplastic polymers within the mold during the filling phase. The analysis calculates the flow front incrementally past the part from the injection location. Flow continues until the velocity pressure switch point.

16+ years 180 sets of equipment 10000 class clean room OEM ODM high precision multi-cavity medical plastic injection mold, medical equipment injection molding and medical and laboratory equipment shells and shells, etc., used in the health care industry, welcome to consult.