Peek is one of the common Teflon materials, PEEK is a high temperature special engineering plastic of thermoplastic material, which can be molded by injection molding.Today we discuss about Teflon plastic injection mold Design Review of gate& runner.

Between these two endpoints, the resin is distributed through the runners, called the runner system. Sometimes, multiple components can be supplied by a single runner.

But things get more complicated when a part has more than one gate. Therefore more runners are required. In a multi-cavity or group mold, each cavity has more than one part (but still only one sprue).

1. The runner design needs to ensure that the resin flows smoothly. Minimize the pressure loss at the runner during the injection molding process.

2 Multi-cavity molds. The flow balance of the runner must be ensured. If necessary, a Meltfliper analysis must be performed to optimize the flow balance of the runner

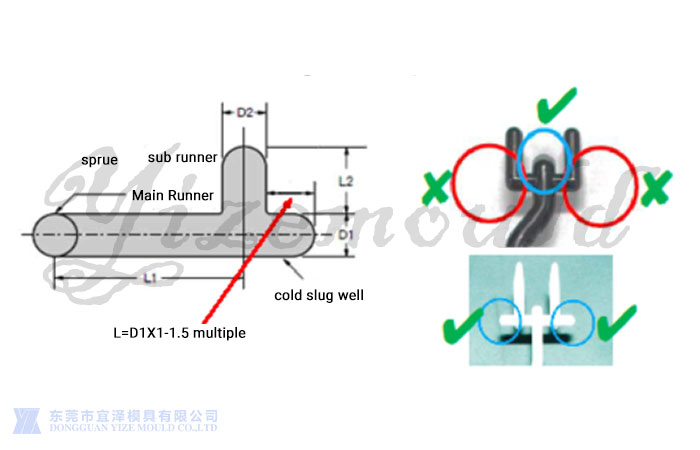

3. The runner design needs to avoid blocking the gate during the flow process. The smelting well must be set to avoid the generation of cold material.

4. Short-cycle molds or thin-walled parts of the product. Pay attention to the thickness of the runner to avoid the runner's negotiation time being too long and affecting the cycletime.

5. The runner needs to be set up with inserts on the mold core.

1. The commonly used runner shapes are round and U-shaped. Except for special cases, the general runner shape is selected as "u"-shaped runner.

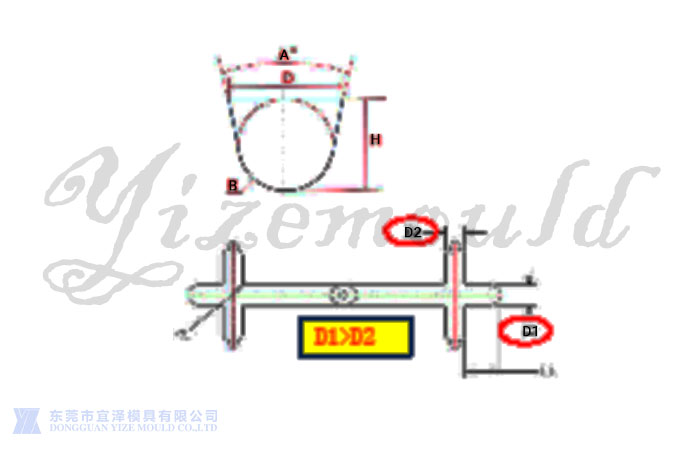

2. The "u" type runner diameter is selected according to the size and model in the table below. When the main channel is transferred to the runner, the runner monster needs to be gradually decreased in units of 0.5.

A Cold Slug Well must be set on the head of the runner to prevent the smelting material from blocking the gate

Teflon plastic injection mold Design Notes:

1. Gate parts disassembly and material.

2. It is necessary to split the template runner.

3. Design of cold material well, corner R.

Yizemould have 125 employees for Teflon plastic injection mold processing. Choose PFA 440HPB PEEK FEP PPS MPTFE ETFE. Precision injection accuracy 0.003mm, injection molding 0.02mm.