Mold NO:21-xxxxx

Customer :TE

Part No :16xxxx-xx

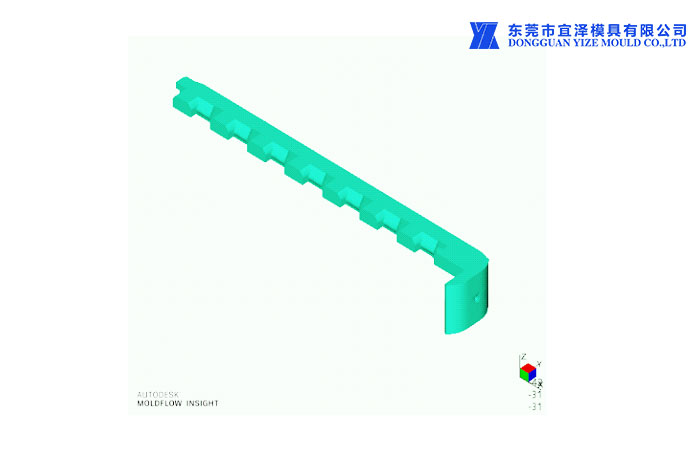

Part Name :TPA

3D Revision/Date :2021.07.14

Drawing No & Rev. :A5

Material :PA66-GF15(Ultramid® A3EG3)

Shrinkage :1.005

Mold Type (2/3plates) :2P

Gate Type /Hot runner supplier name :Hot Cold(Synventive)

Injection Machine :15T

Cavity quantity :4

Analysis aim: Validation of the part structure and the mold connector mould design.

Mesh (Moldflow 2019 SP1)

Our company is able to provide customers with Moldflow analysis (high-end plastic injection molding computer-aided engineering simulation software)

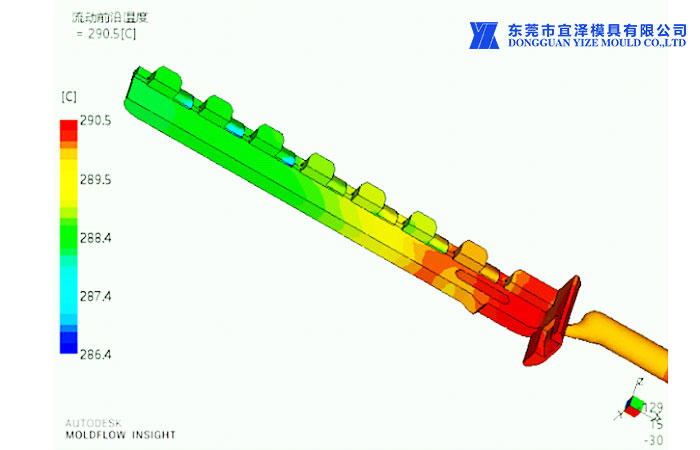

Uniform temperature at flow front.

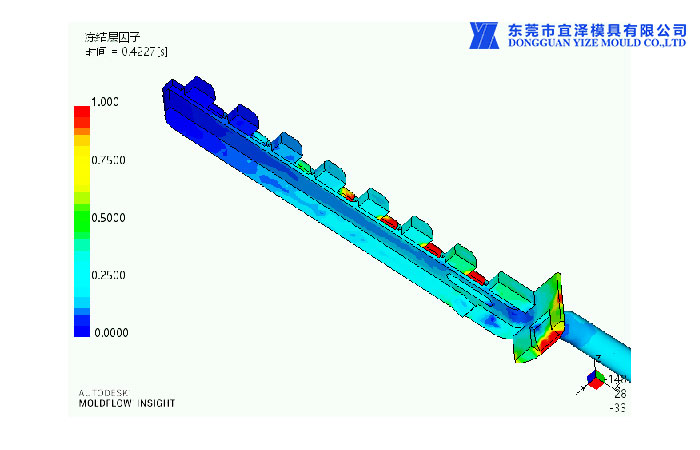

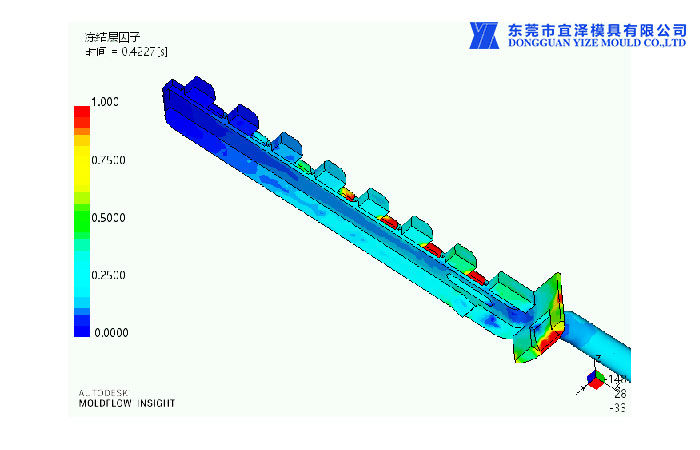

Analysis Results: Short shot possibility

No hesitation flow and Filling smoothly;

Filling pressure is OK.

Please pay attention to strengthen vent at the regions of weld lines and last filled,

Please check whether the part deflection meets the assembly tolerance.

The layout of the runner & cooling system was created according to the analyst’s experience, which might be different from the actual mold structure;

The molding process parameter is recommended by the resin vendor, which might be different from the actual Connector Mould parameter;