Leaked or condensed water can cause great damage to high precision plastic injection mold rust and cavities. Sometimes it's really bad mold rust that costs thousands of dollars to repair, there's a lot of personal stress in dealing with downtime and trying to make quality parts. If water or condensate stays long enough, it can cause serious damage

Why does the high precision plastic injection mold rust?

1. Do not use water but oil during mold production.

2. Check whether the mold is leaking, if it leaks, the mold is really easy to rust.

3. Generally, it is difficult to rust when transporting water at work, because water is needed, and the chemical reaction will occur only when oxygen is added to the iron. After use, blow out the liquid inside with an air gun, coat the mold with anti-rust oil, pack it and send it to the mold bin.

How to avoid high precision plastic injection mold rust?

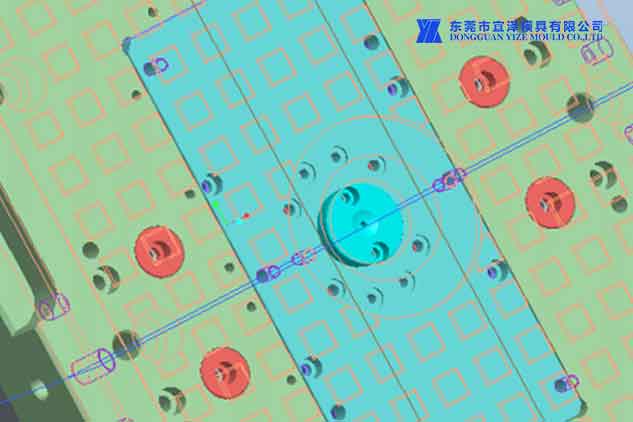

High precision plastic injection mold project Design:

1. Try not to use the structure of turning the water on the back plate to avoid rusting

2. Consider the steel and anti-rust treatment of the formwork

3. The length and flow of the waterway should be considered

Assembly/Test:

① Test the actual flow of the waterway;

② Dry the residual water immediately after the mold is off the machine.

③ Real-time monitoring of mold temperature and production data