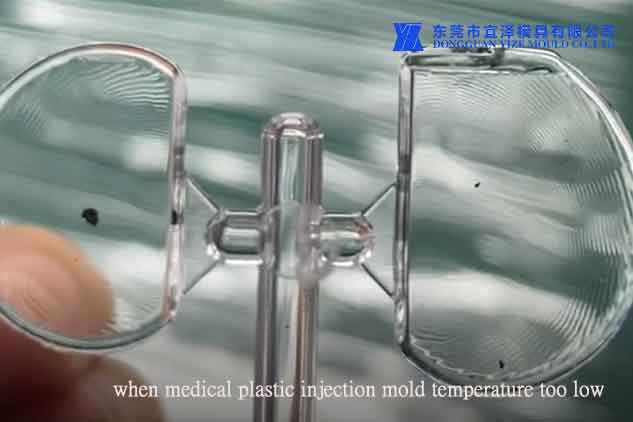

If the cooling system design of the mold is ineffective or the temperature of the medical plastic injection mold is not properly regulated, the plastic part will not be adequately cooled.

As a result, the plastic part will warp and deform. The influence of medical plastic injection mold temperature on deformation can be seen to be very significant. Here are two suggestions for analyzing mold temperature:

1. Deformation

The mold temperature is stable and the cooling rate is balanced to reduce the deformation of the product. For products with inconsistent wall thickness and complex shapes, deformation due to uneven shrinkage often occurs.

Using the medical plastic injection mold temperature adjustment system to keep the mold temperature constant can reduce the fluctuation of the molding shrinkage rate of the product. Dimensional accuracy will be improved as a result. Using a lower mold temperature when possible can help reduce the molding shrinkage of the product.

2. Surface quality

Increasing the Medical plastic injection mold temperature can improve the surface quality of the product. By using a low mold temperature, the contour of the product becomes unclear, resulting in obvious fusion lines and an increase in surface roughness.

Excessive mold temperature differences will cause uneven cooling and inconsistent shrinkage of plastic parts. As a result, parts with uneven wall thicknesses and complex shapes will be stressed and warped. On the side with a high mold temperature, after the product is cooled, the deformation direction must be toward the side with a high mold temperature! The temperature should be adjusted according to the needs of the front and rear molds. For the mold temperature, see the physical property tables of various materials!

We specialize in the research and development, production, sales, and service of medical plastic injection mold device. At this stage, we are very familiar with the development of medical consumables in China, as well as the product use and requirements of many medical consumables.