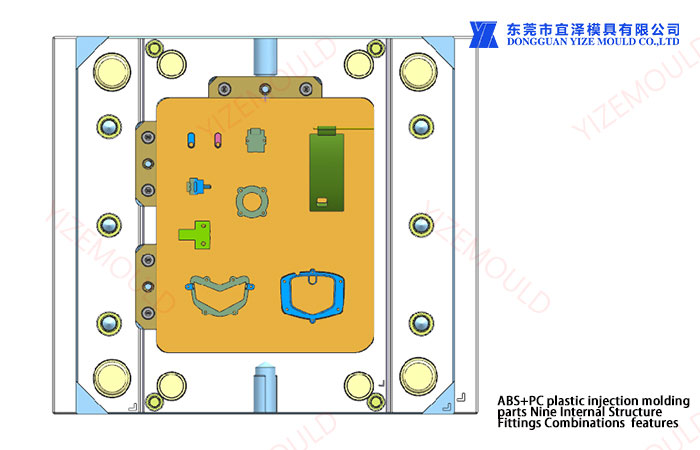

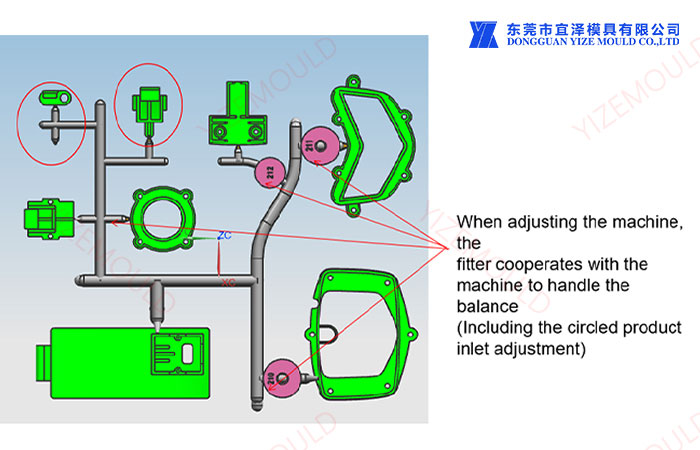

ABS+PC plastic injection molding parts Nine Internal Structure Fittings Combinations

Material :PC+ABS

Shrinkage :1.005

Gate Type /Hot runner supplier name :Cold Runner

Mold Type (2/3plates) :2P

Cavity quantity :9X1

Features

1. Electronic and electrical products

2. Good flame retardant effect and UV resistance

3. High strength and good toughness, subzero cold resistance

4. Excellent forming performance

5. It is necessary to maintain the balance of the glue to avoid burning and trapping air, shrinking the surface, and serious shooting lines.

This ABS+PC plastic injection molding parts application

1. Injection molding

2.5G communication product shell

3. Electronic and electrical enclosures

4. Automotive structural parts

ABS+PC plastic injection molding parts material requirements: pass the cold resistance test

1. Unparalleled cold resistance, good impact performance in the harsh environment of ice and snow. At -40℃, the impact and viscosity balance of the same kind of raw materials is the same

2. Weather resistance Long-term exposure to the outdoors, still maintains good mechanical impact properties

3. Anti-aging, put the color plate in the refrigerator at minus 40 degrees for 24 hours to do the ball drop test

4. Chemical resistance: Compared with standard PC plastic, the chemical resistance formula is added, and the chemical resistance is improved compared with standard PC.

5. Weld line strength

6. Flame retardancy

7. Glass fiber reinforced has higher strength to meet the requirements of increasing users

8. Few mold deposits during molding, better mold release

Whether you want more information on professional plastic injection molding parts service, need help with what you're creating, want to collaborate or just say hello! ---We would love to hear from you.