Service Items: Snap button plastic injection molding parts design, mold opening, and injection molding

Description of the basic situation of the customer: Wuhan Electronics Group Co., Ltd.

It is a high-tech enterprise dedicated to providing excellent products and services for semiconductors, displays, new energy, and other testing fields.

Product requirement

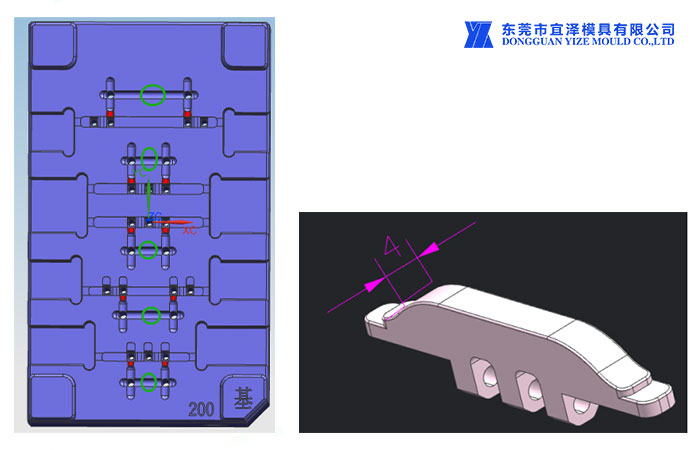

1.5 products are evaluated for a common mode of Snap button plastic injection molding parts, and only one set of molds is opened.

2. The overall appearance refers to the appearance sample of the workpiece

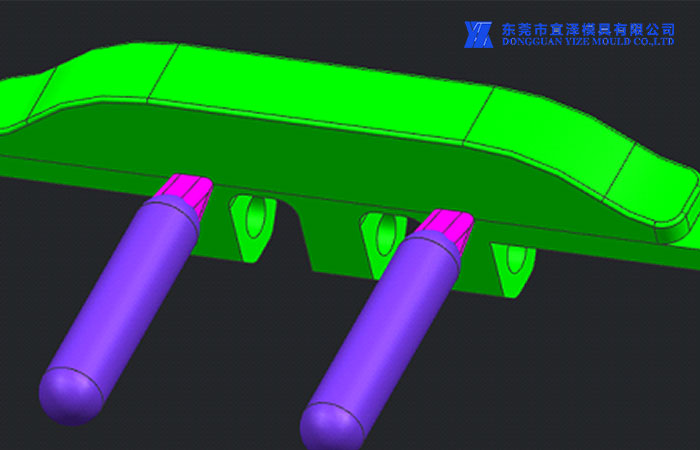

3. It is not allowed to have thimble marks and glue feeding points.

4. The surface of the product needs to be anti-static

Snap button plastic injection molding parts difficulties to be overcome:

A variety of products of different shapes are injected at the same time, which is prone to shrinkage, strain, and parting line difference

2. The anti-static value of products made of PEEK material is narrowed, and the anti-static value is controlled at 106-109.

Solution:

We finally modified its gate type method

2. On the basis of the original design, 0.5° glue reduction and draft;

3. Apply to increase the draft angle to 1°

Yize is determined to become a world-class excellent plastic injection molding parts factroy, create value and promote the development of the engineering injection mold industry.