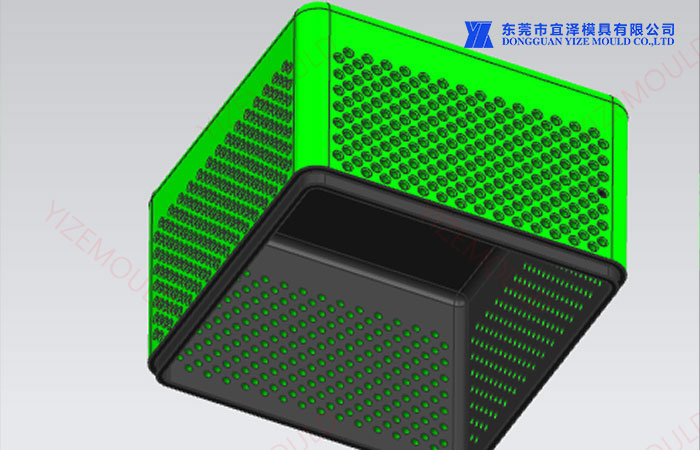

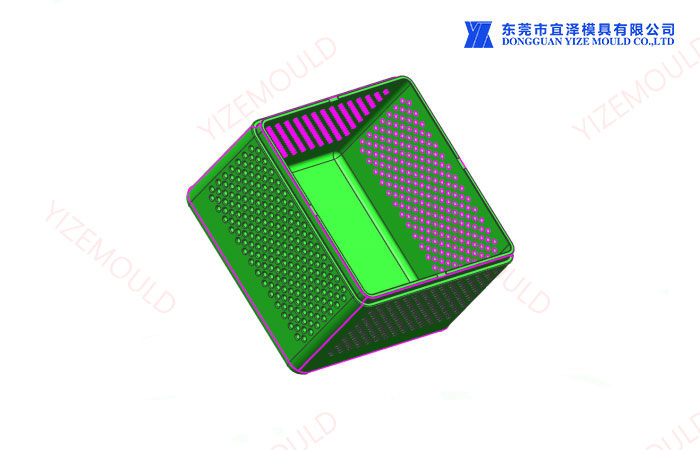

The basic information on PC plastic injection molding parts is as follows:

Number of mold cavities: 1*1

Product material: PC

Material Type Covestro: 2405

color: black

Product net weight: 44.895g

Feed weight: 10.825g

Estimated weight: 4kg

Machine model: 50T

Customer requirements:

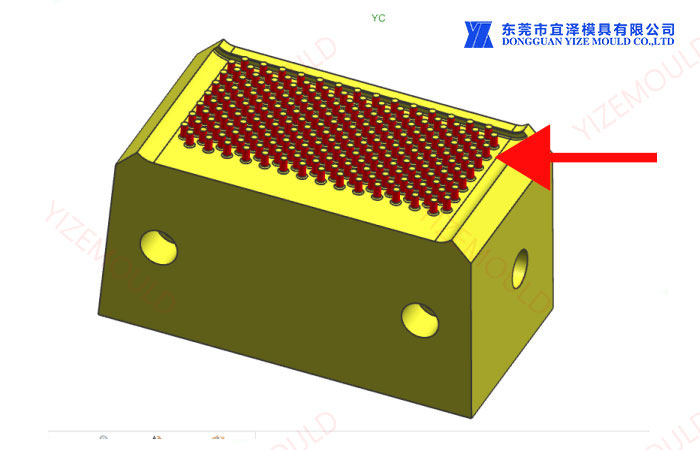

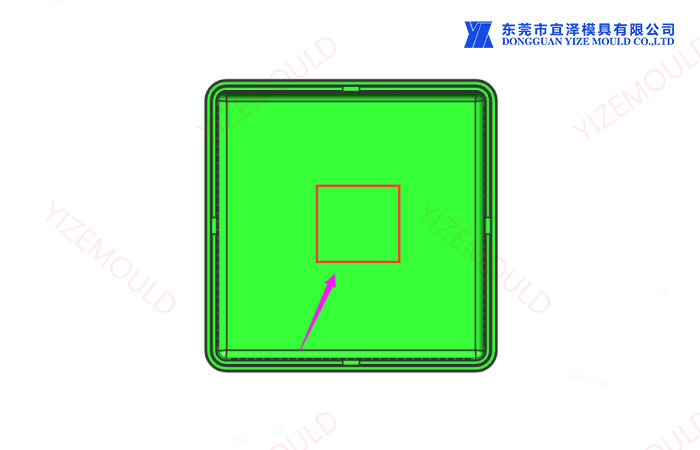

The red arrow is the angle of mutual cooperation of the sliders. Pay attention to the machining accuracy and do not sag.

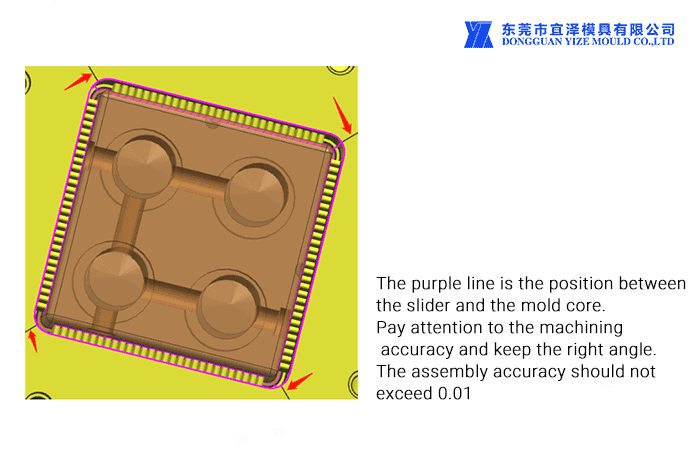

The purple line is the position between the slider and the mold core. Pay attention to the machining accuracy and keep the right angle. The assembly accuracy should not exceed 0.01

Cause problems:

Die sticking and air trapping during injection molding on PC plastic injection molding parts

Sticky mold concept:

sticky mold, also known as Sticking Sprues or Parts, is due to the poor contact surface between the injection port and the nozzle arc, the gate material is not demolded with the product, and the abnormal filler. Usually, the diameter of the sprue should be large enough so that the gate material is not fully cured when the mold is released.

Definition of tiredness

air trapping refers to the phenomenon that in the process of filling the mold cavity with injection, the gas in the mold cavity cannot be discharged in time or from the injection mold, which prevents the compound from continuing to fill, resulting in injection defects such as lack of material and burning. Under normal circumstances, air trapping occurs in the process of filling the mold cavity, and does not occur during the process of maintaining pressure and feeding. The gas in the mold cavity has two sources: one source is the air in the mold cavity, and the other source is the decomposition gas and a small amount of water vapor generated by the compound itself

Solution:

PIN post increases the draft angle

Add exhaust inserts in the middle of the PC plastic injection molding parts

Scientific plastic injection molding parts testing realizes the optimal control method of the injection molding process to provide a shorter molding cycle, higher production yield, and a more stable injection molding procedure. The plastic flow behavior inside the mold is the key to determining the quality of the product, not the purchase of expensive equipment.