Customer introduction:

GN Group

Gn is an intelligent audio and video communications company dedicated to facilitating human-to-human communication in smart hearing, audio, video and gaming technologies.

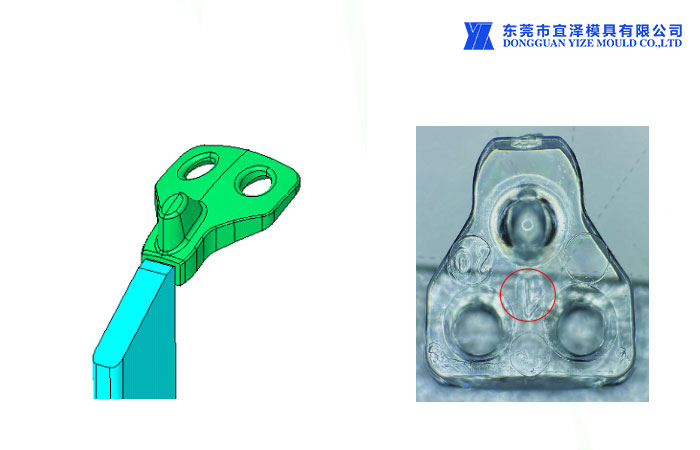

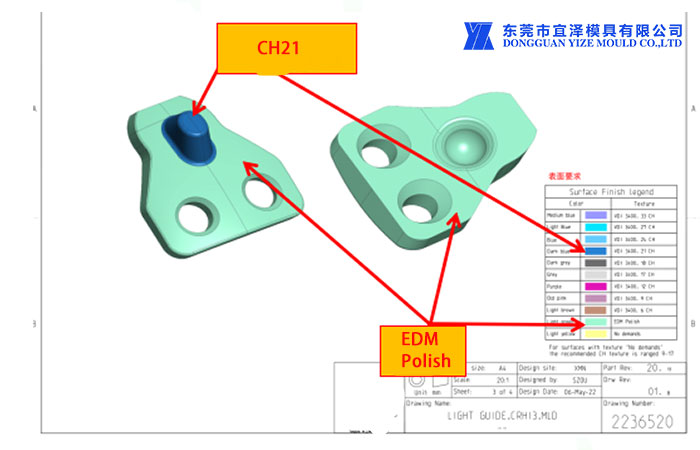

Product Name: Module Base (Bracket)

Medical devices plastic injection molding parts information

Plastic material :Makrolon® 2858

Shrinkage: 1.005

Tooling type :2 plate

No. of cavities :04

Medical devices plastic injection molding parts requirement

1.Using for Hearing protection

2. Ensure surface finish

According to the data collected by Yizemould and the requirements and tests for product performance,we suggest choose the Makrolon® 2858 for Medical devices plastic injection molding parts

Makrolon® 2858 advantage as below:

MVR (300 °C/1.2 kg) 9.0 cm³/10 min;

suitable for ETO and steam sterilization at 121 °C;

biocompatible according to many ISO 10993-1 test requirements;

medium viscosity;

We are willing to face difficulties and grow together with our customers, through the joint efforts of both parties, the product will be put into trial operation in 2022 and equipped with related products to promote only the European and American markets.