PPA plastic injection molding parts electronic components details as follow:

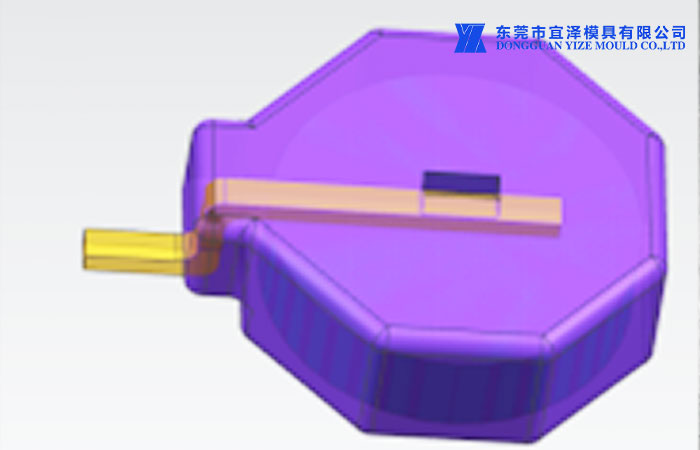

Part Name: 7D-10D

Material: PPA

Shrinkage: 1.005

Mold Type (2/3plates) :2P

Gate Type /Hot runner :Cold Runner

Cavity: 2+2

Customer requirements for PPA plastic injection molding parts:

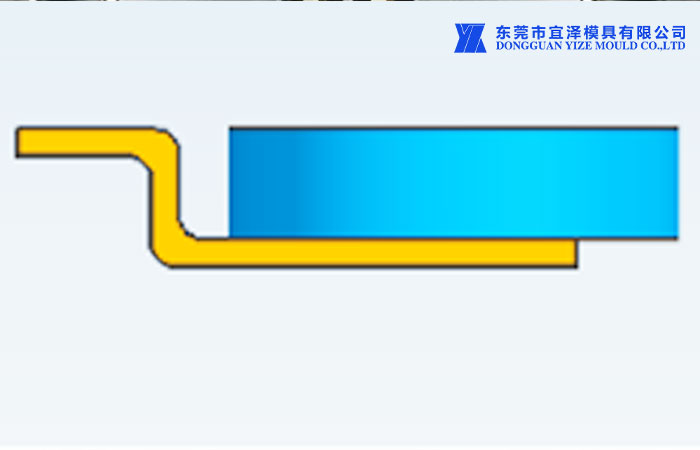

1. Terminal bending tolerance ±0.5°

2. The tolerance of the rectangular cross-section (red area) of the product hardware terminal is required to be controlled within ±0.015

3. The bending angle requirements of product hardware terminals are consistent, and the bending tolerance is ±0.5

4. Please ensure the consistency of the product hardware terminal welding, and the tolerance of the center position of the chip is ±0.05.

PPA plastic injection molding parts Application: Provides a tailor-made portfolio of electrical and electronic products, bringing new developments to power or data transmission connectors used in automotive, electrical and consumer electronics, as well as electric vehicle components, miniature circuit breakers, switchgear and sensors possible.

All flame retardant materials in the PPA portfolio maintain their high mechanical properties and dielectric strength at elevated temperatures.

We drive profitable growth and business development through our close collaboration with our customers and our focus on plastic injection molding parts project. The strong R&D strength has laid a solid foundation for the development of innovative products and applications.