With the development of science and technology, industry is becoming more and more specialized, and the requirements for products and equipment are becoming higher and higher. Therefore, the demand for tube and tube fittings that are resistant to high temperature, abrasion and chemical corrosion, and can be applied to transport a variety of corrosive and viscous plastics has arisen.

As a company dedicated to providing solutions to our customers, Yize Mould was determined to develop relevant products. We found that PFA(perfluoroalkoxy), as a material with excellent chemical stability, physico-mechanical properties, electrical insulation, lubricity, non-stickiness, aging resistance, non-flammability and thermal stability, could precisely meet the above mentioned needs in terms of physical and chemical properties for pipe interfaces. Together with our previous experience in designing and manufacturing PFA products, we have accumulated a certain amount of know-how.

However, during the development process, we still encountered many technical difficulties, most notably are the corrosive gases generated during the processing of PFA, as well as higher product purity requirements.

The standard processing temperature for PFA is 380°C(716℉), with a small amount of decomposition during the process. Thermal decomposition of fluorine resin will produce fluorine olefins (such as TFE), oxidation products (such as fluorine gas COF2), hydrogen fluoride (HF), and low molecular weight polymer particles, and even a little but highly toxic substances PFIB. Coupled with the high purity requirements of the product, so in the selection of the PFA mold material, commonly used mold materials, such as S136 and so on, will be subject to chemical corrosion, and the need for nickel alloys made of molds. In addition, the cutter head for stirring PFA particles is also prone to corrosion during processing, thus bringing some of the metal impurities into the product. Thanks to the unremitting efforts of our technical team, we were able to overcome this technical difficulty.

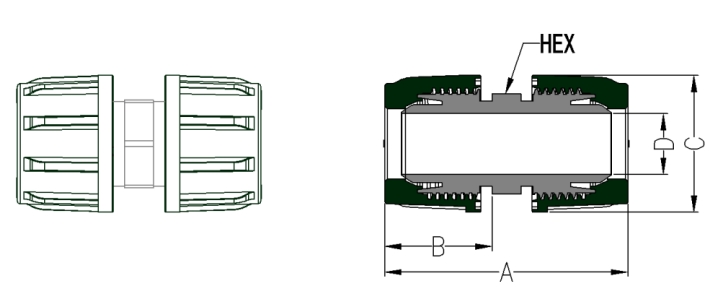

At present, the first batch of our patented products (PFA straight connector) has been successfully put into production, there are five models: 1", 3/4", 1/2", 3/8", 1/4", the working temperature range is up to -40℃~240℃ (-40℉~464℉), and the maximum working pressure is up to 1.5MPa. The rest of the pipe connectors will be successfully put into production within one year.

Of course, PFA, as an emerging material with excellent abrasion resistance, chemical stability, and thermal stability, has a wide range of application that go far beyond tube fittings. In the next article, we will answer such a question: What are the applications of PFA?

If you have any other questions, welcome to contact us, we will try our best to answer your questions.

Fluoroplastics Series:

Fluoroplastics Series (1) - Yize Mould had successfully design and manufacture PFA tube fittings

Fluoroplastics Series (2) - What are the Applications of PFA?

Fluoroplastics Series (3) - What are the similarities and differences between PFA and PTFE?

Fluoroplastics Series (4) - What are the applications of PTFE?

Fluoroplastics Series (5) - What is PVDF?

Fluoroplastics Series (6)--New Applications of PVDF

Fluoroplastics Series (7) - FEP performance

Fluoroplastics Series (8) - Application of FEP