Expansion-type PFA ElbowTeflon plastic injection mold project introduction

Flare PFA ElbowTeflon plastic injection mold project features:

◆100% produced by Japanese Daikin 211SH high-purity raw materials

◆Produced in a 100,000-class clean room, the cleanliness is guaranteed

◆Vacuum packaging to avoid product contamination

◆Individual carton packaging to avoid product damage

◆Expanded spring clip structure to improve the increase

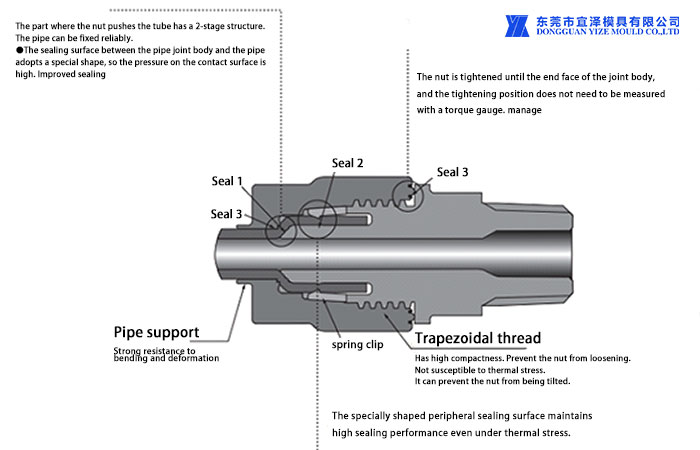

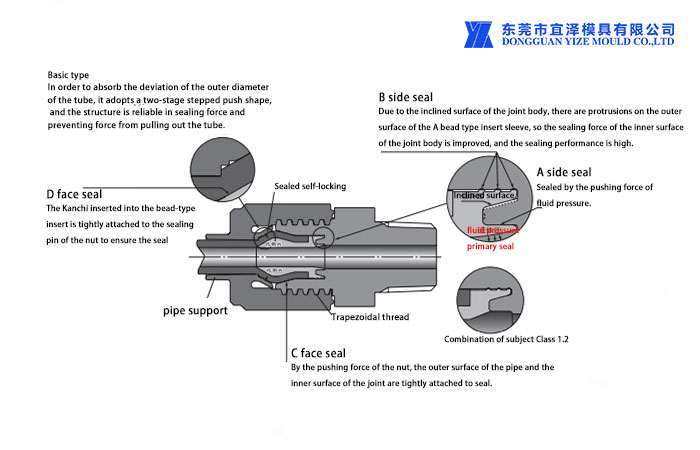

◆3-layer sealed structure

◆Good assembly and constructability

◆Excellent fluid displacement characteristics

◆ Strong thermal stress resistance, corresponding to 260℃

Beaded PFA ElbowTeflon plastic injection mold project introduction

installation guide

1. Flared joint installation method

1. Pipe flare

①Use a pipe cutter to cut the pipe flat and insert it from the non-threaded side of the nut

②Insert the hose into the expander, press the hose lightly until it is inserted to the bottom

③ Expand the tool from 10% to 20%

④Release hand pressure, rotate the tube, and press the handle again

⑤Repeat step 3 and step 4, gradually increase the pressure until the tool is fully expanded

⑥ Put the expanded pipe into the flared end of the joint, and install the nut until it is tightened.

It is composed of PFA Teflon plastic injection mold joint body, nut and ferrule, connected with threaded ferrule, with good sealing performance, and can be connected to pipes and other equipment. It can be used as a pipeline connection for various chromatographs and chemical equipment. Divided into different diameters. We can customize according to your specification, shape and size.